Opening

Did you know that CNC machining has revolutionized the manufacturing industry, enabling precision engineering with tolerances as tight as ±0.001 inches? As companies around the globe continue to seek ways to enhance productivity and reduce costs, the role of CNC aluminum processing plants has become critical in providing comprehensive engineering support and technical consulting. For businesses invested in components that require both detailed engineering insight and advanced metallurgical knowledge, the question arises: how can CNC aluminum processing plants deliver value beyond basic machining?

Understanding the Role of CNC Aluminum Processing Plants

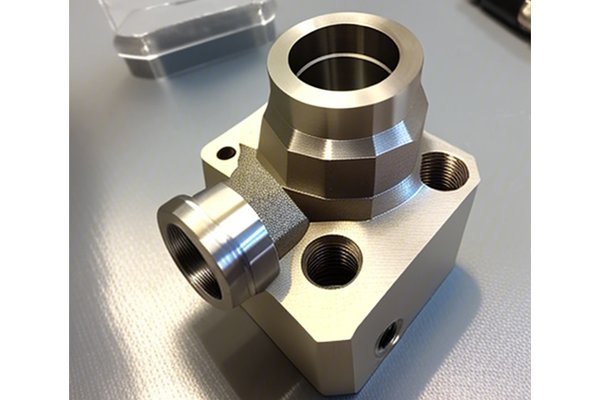

CNC (Computer Numerical Control) machining refers to automated control of machining tools by means of a computer. This precision technology is particularly vital when working with aluminum, a material known for its lightweight properties, high strength-to-weight ratio, and excellent corrosion resistance. In the context of CNC aluminum processing plants, an investment in technical consulting and engineering support becomes essential for several key reasons:

The Essential Engineering Support Offered by CNC Aluminum Processing Plants

DFM is a principle engrained in CNC aluminum processing that helps identify potential manufacturing challenges before they arise. Involving engineers in the design phase allows for collaborative reviews that lead to optimized geometry, simplified assembly, and reduced production costs. Engineers use simulation software to visualize and analyze machining setups, ensuring that designs conform to machining capabilities.

Each aluminum alloy comes with its unique attributes and limitations. A knowledgeable CNC processing team can offer insights about which alloy to select based on strength, weight, corrosion resistance, weldability, and thermal properties. When clients present their needs, engineering teams can recommend the most appropriate materials, potentially saving significant costs in material purchases and enhancing the overall performance of the final product.

CNC facilities offer customization in both design and production. Whether the need is for complex geometries or specific tolerance levels, engineering consultants can design tailored solutions that meet the exacting specifications of clients. Advanced CAM (Computer-Aided Manufacturing) software can simulate the machining process, helping engineers address potential issues before they manifest on the shop floor.

Rapid prototyping is a crucial aspect of modern manufacturing, enabling clients to visualize their designs in real-world applications. CNC aluminum processing plants can provide prototyping services that offer insights on performance, dimensions, and even aesthetic appeal before large-scale production begins. This allows clients to adjust their designs based on tangible feedback rather than theoretical assumptions.

Continuous support and consultation help clients during various project stages. They can inquire about machining techniques, surface finishes, tolerances, or specific machining strategies. Collaboration with engineering experts can lead to improved decision-making and heightened project confidence.

Throughout the machining cycle, challenges may arise—be it tool wear, surface finish discrepancies, or machine reliability issues. CNC processing plants often conduct analyses to identify the root cause of production challenges and suggest preventive actions. This real-time feedback loop is essential for continuous process improvement.

The Impact of Engineering Support on Production Efficiency

The integration of engineering support and technical consulting in CNC aluminum processing is not merely about optimization; it has profound implications for a company’s bottom line. Here are some ways in which enhanced engineering involvement influences production efficiency:

In the competitive landscape of modern manufacturing, CNC aluminum processing plants provide a crucial blend of engineering support and technical consulting, making them indispensable partners for businesses aiming to remain agile and responsive to market demands. By incorporating techniques such as DFM, material expertise, customized solutions, prototyping, technical consultation, and troubleshooting, these plants enable companies to navigate complexities with confidence.

As businesses continue to innovate and upscale their production capabilities, understanding the role of CNC aluminum processing facilities and their engineering support services will be instrumental in achieving pursuit of quality and efficiency. Engaging with a knowledgeable partner can significantly impact product outcomes, cost structures, and project timelines.

In today’s manufacturing environment, it’s time to rethink reliance on basic machining services. By embracing the full suite of engineering expertise offered by CNC aluminum processing plants, organizations can position themselves to succeed in an increasingly intricate industry landscape. The question is no longer whether to utilize these services but how fully to integrate them for maximum benefit.