Opening:

Did you know that according to a recent survey, nearly 30% of manufacturers report delays in their CNC machining process, leading to significant losses in both time and revenue? In an industry where precision and timely delivery are paramount, organizations must actively pursue strategies to enhance the efficiency and reliability of CNC (Computer Numerical Control) processing, especially in mass production. The stakes are high; maintaining quality while meeting delivery deadlines can be the difference between gaining repeat customers or losing them to competitors.

—

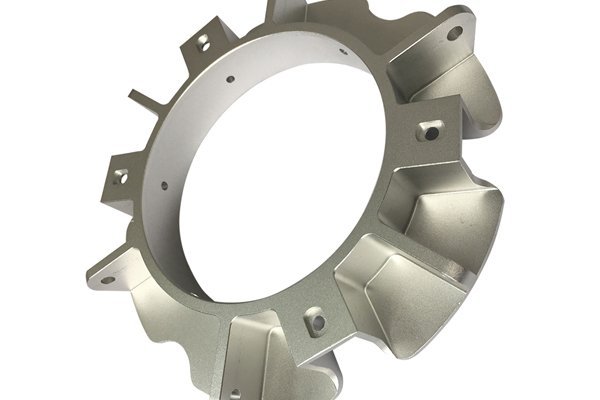

Before diving into the solutions for perfect delivery times and quality control, it’s crucial to understand what CNC processing is and why it plays a significant role in mass production. CNC machining uses computer-generated codes to control machinery to produce high-precision parts. Applications range from aerospace to medical devices, where quality and timelines are non-negotiable.

—

Why are delivery time and quality so critical in CNC processing? Slow delivery may lead to project delays, increased costs, and dissatisfied clients. Quality concerns can result in costly reworks, wastage, and loss of reputation. Achieving both delivery and quality simultaneously is a delicate balance and requires sophisticated planning and execution.

—

Achieving timely delivery in CNC processing necessitates a multi-faceted strategy:

a. Accurate Production Scheduling

Use software tools to program not just the production cycles but also the setup times for new jobs. Create a detailed schedule that reduces downtime and ensures predictable workflow.

b. Utilize Lean Manufacturing Principles

Apply lean practices to streamline processes by eliminating waste. For instance, employing just-in-time (JIT) manufacturing reduces inventory costs and helps align production with customer demand.

c. Implement Real-Time Tracking

Real-time tracking technologies can provide insights into production statuses, allowing for immediate adjustments to avoid delays. This can include everything from machine uptime to the availability of raw materials.

d. Cross-Training Employees

When employees are cross-trained, they can step in and handle varying tasks as needed. This flexibility can tremendously reduce bottlenecks and maintain production continuity, particularly during higher periods of demand.

e. Supply Chain Optimization

Maintain close relationships with suppliers to ensure that necessary materials are available when required. Employ techniques such as bulk ordering and strategic partnerships to keep the supply chains robust.

—

Quality assurance must not be a mere afterthought but an integral part of the manufacturing process. Here are ways to ensure high-quality CNC products:

a. Implement Robust Quality Management Systems

Quality Management Systems (QMS) are essential for setting quality benchmarks and documenting processes. ISO 9001 standards can serve as a guiding framework here.

b. Regular Equipment Maintenance

Schedule regular calibration and preventative maintenance for CNC machines. This will ensure that the machinery performs optimally and reduces defects caused by miscalibration.

c. Adopt Statistical Process Control (SPC)

Using SPC techniques allows the monitoring of critical processes in real time. Control charts can help identify variations in production, making it easier to pinpoint issues before they escalate.

d. Continuous Training and Upskilling

Train your workforce regularly to keep them abreast of best practices and new technologies. Skilled workers make fewer errors, which in turn boosts the overall quality of the output.

—

Technological integration plays a significant role in ensuring both quality and efficiency:

a. CNC Programming Software

Invest in advanced CNC programming software that allows for simulation and optimization of machining processes. This software can reduce the likelihood of errors and improve machining efficiency.

b. CAD/CAM Systems

Utilize CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) systems to bridge the gap between designing and manufacturing. These integrated systems enhance precision during design hand-offs, significantly improving quality and reducing reworks.

c. Automation and Robotics

Automating repetitive tasks and using robotics can improve speed while maintaining high quality levels. Automated inspection systems can further reduce human error during quality checks.

—

Transparent communication with stakeholders can help streamline operations:

a. Regular Client Updates

Keep clients informed about production timelines and any potential delays. Effective communication can manage expectations and foster trust.

b. Internally, Foster Team Collaboration

Ensure that different departments (sales, production, quality control) communicate effectively with one another. A cohesive team is more likely to identify problems early on.

—

Keeping up with relevant standards can drastically improve quality and effectiveness:

a. Understanding ISO Standards

Familiarize yourself with different ISO standards relevant to your manufacturing processes. Adopting these can not only help in delivering quality but also improve credibility in the market.

b. Compliance with Industry Regulations

Ensure compliance with necessary industry regulations, especially in critical sectors such as automotive and aerospace. Regulatory updates must be communicated and implemented throughout the production process.

—

In the realm of CNC processing, achieving the dual objectives of timely delivery and high quality demands meticulous planning, ongoing training, and technology integration. By implementing strategic measures such as accurate scheduling, strong quality management systems, and embracing technology, manufacturers can navigate the complexities of mass production with greater assurance.

This blog underscores the importance of being proactive in both delivery and quality assurance practices. In a highly competitive market, continuously refining these processes gives manufacturers the upper hand needed to thrive. Think of it as not merely a process but a continuous journey toward excellence. Remember, in the world of CNC machining, it’s not just about making parts; it’s about making parts that can deliver value, meeting both customer timelines and quality expectations without compromise.

Keep these strategies in mind as you refine your CNC processes and watch your production floor become more efficient, reliable, and respected in your industry.