Opening

Imagine a world where intricate designs and complex geometries can be produced with precision at scale—this is the promise of CNC machining. But when it comes to special-shaped parts, engineers and manufacturers often encounter a significant hurdle. Did you know that a staggering 70% of machining problems stem from design complexity? This statistic highlights just how critical it is to address the challenges related to manufacturing special-shaped components. In this blog, we’ll explore the multitude of challenges posed by CNC machining special-shaped parts and offer detailed solutions that can help manufacturers optimize their processes.

Understanding CNC Machining and Special-Shaped Parts

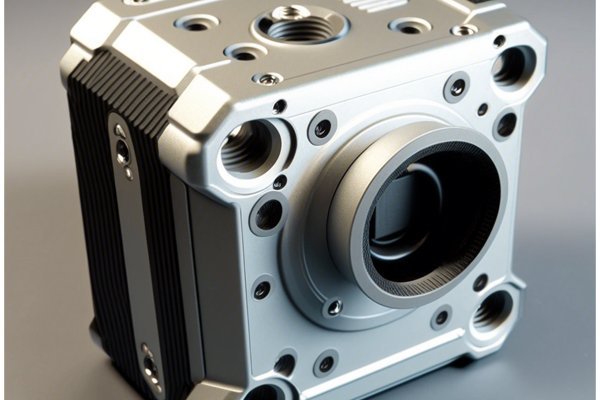

CNC (Computer Numerical Control) machining is a popular manufacturing process that automates the movement of machine tools using computer programming. It allows for high levels of accuracy and repeatability in producing parts from various materials, including metals, plastics, and composites. However, when it comes to special-shaped parts—those that do not conform to standard geometry—manufacturers must navigate a series of unique challenges.

The Challenges of CNC Machining Special-Shaped Parts

Solutions to Overcome These Challenges

Real-World Case Studies

In the aerospace sector, a leading manufacturer faced challenges in machining complex airfoil shapes for turbine blades. By investing in advanced CAD/CAM software and specialized tooling, they reduced their machining time by 30% while improving dimensional accuracy. This not only saved costs but also enhanced the performance of the final product.

A company specializing in medical implants encountered difficulties machining complex bio-compatible shapes. By adopting new fixturing methods and optimized tool paths, they increased their production rate by 25% and significantly lowered their defect rate.

The CNC machining of special-shaped parts presents unique challenges, from complex geometries to the need for advanced tooling and optimized processes. By leveraging modern technology and innovative techniques, manufacturers can effectively overcome these hurdles, leading to higher efficiency and better-quality products.

As the demand for intricate and specialized components continues to rise across various industries, the strategies discussed in this blog will remain crucial. The importance of addressing these challenges cannot be overstated: they can dictate the difference between successful manufacturing and costly errors. For engineers, production managers, and business owners, understanding how to effectively tackle the complexities of CNC machining can pave the way for sustainable growth and innovation.

By focusing on continuous improvement, investing in the right tools, and implementing robust quality assurance processes, you can stay ahead in an increasingly competitive landscape. Special-shaped parts may challenge traditional machining methods, but with the right approach and technology, they can also unlock new opportunities for creativity and functionality in product design.