The : A Surprising Insight

Did you know that titanium alloys are known for their exceptional strength-to-weight ratio and corrosion resistance, making them a popular choice in industries ranging from aerospace to medical devices? According to a report by the market research firm Research and Markets, the global titanium alloys market size was projected to reach approximately $3.1 billion by 2026, growing at a CAGR of 5.6% during the forecast period. Despite their advantages, achieving a high-quality surface finish after CNC (Computer Numerical Control) processing of titanium alloys can be a daunting challenge. This blog delves into the intricacies of improving the surface finish of titanium alloy parts post-CNC machining, providing you with actionable techniques and technologies.

Understanding the Challenges of CNC Machining Titanium Alloys

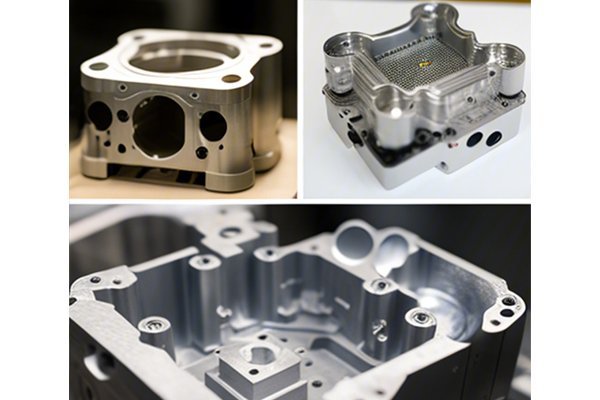

CNC machining of titanium alloys is a specialized process that presents unique challenges compared to machining more common materials like aluminum or steel. Some of the primary challenges include:

Strategies for Achieving Superior Surface Finishes

Improving the surface finish of CNC machined titanium alloys requires a comprehensive approach that encompasses tool selection, machining parameters, and post-processing techniques. Let’s explore in detail how to tackle these challenges.

The choice of tooling is critical when machining titanium alloys. The following considerations should guide your tool selection:

Finding the right balance in cutting parameters significantly affects the surface finish. Here are key parameters to fine-tune:

Using the right cooling strategies can significantly impact the surface finish. Here are some recommended methods:

Even after careful machining, enhancing surface finish may require additional post-processing methods:

: The Journey to Perfection

Improving the finish of parts after CNC processing of titanium alloys is not just a matter of selecting the right machine settings or tools; it is a comprehensive process involving various techniques that work in harmony to yield optimal results. By meticulously selecting the right tools, optimizing machining parameters, employing effective coolant strategies, and considering post-processing methods, manufacturers can significantly enhance the surface finish of titanium components.

This blog highlights the importance of each parameter and technique, emphasizing why understanding these aspects is crucial for professionals in the field. As technology advances, maintaining a focus on quality control and innovation will be essential to navigating the evolving landscape of titanium alloy machining. By implementing these strategies, businesses can ensure superior product quality, ultimately leading to better performance and satisfaction in applications where titanium alloys are deployed.

Your Next Steps

As you consider the practices discussed in this blog, think about how they can be integrated into your existing CNC machining processes. Continuous improvement in machining practices often leads to increased efficiency, reduced costs, and a significant boost in product quality. The journey toward achieving impeccable surface finishes is ongoing, and reflection on the techniques shared here will prove invaluable.