Did you know that the choice of material can disproportionately affect the efficiency, cost, and accuracy of CNC machining? According to studies, the wrong material selection can result in up to a 30% increase in machining time and wasted resources. As industries push the boundaries for precision and efficiency, understanding material properties and their impacts on CNC machining has never been more critical.

In a world where manufacturing industries are constantly seeking to optimize processes, selecting the appropriate materials for CNC machining can make a world of difference, especially when working with large parts. In this blog, we will explore how to select materials that enhance efficiency in CNC machining of large components, focusing on factors such as material properties, machining techniques, tooling, and handling processes.

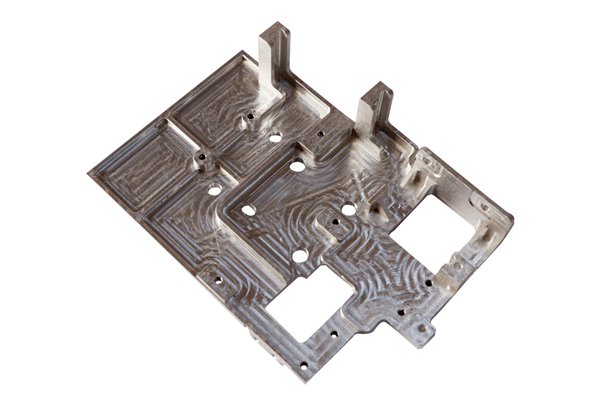

Understanding Material Properties

When selecting material for CNC machining, one must consider mechanical properties such as tensile strength, yield strength, hardness, and toughness. For example:

Thermal properties play a key role when the operational temperatures are high:

In machining environments where exposure to chemicals is inevitable, selecting materials with adequate chemical resistance is crucial. This consideration can affect the durability and integrity of the parts being manufactured.

Some materials are easier to machine than others. Machinability factors include:

Aluminum and brass, for instance, are much easier to machine compared to stainless steel, which can be more challenging but offers better strength and corrosion resistance.

Selecting the Right Material

Understanding the demands of the final product is crucial when selecting materials:

Consider not only the raw material cost but also additional expenses related to tooling, machining time, and post-processing. While some materials may be cheaper upfront, they could lead to higher costs due to tooling wear or longer machining times.

Research potential suppliers for the materials to ensure they meet industry standards. Be wary of inconsistencies in material properties between suppliers, and if necessary, get samples for testing.

Before finalizing material choices, conducting tests on small prototype parts can hinder any unforeseen issues. Testing allows for real-time data collection and helps refine processes before embarking on full-scale production.

Optimizing CNC Machining Processes

The choice of tools can significantly affect the efficiency of machining large parts. The following considerations can be key:

Adjusting the speed, feed rate, and depth of cut can greatly enhance machining efficiency:

When machining large parts, it is essential to streamline the workflow:

Adopting a routine for tool and equipment maintenance can significantly enhance tool life and machining quality. This includes:

Innovations and Emerging Trends

The manufacturing industry is continually evolving, with materials such as composites and alloys gaining popularity due to their favorable properties:

Integrating digital technologies with CNC machining, such as IoT devices and predictive analytics, can lead to data-driven decision making in material selection and machining processes:

With a growing focus on sustainability, selecting materials with recycled content or lower environmental impacts has become crucial. Companies are now more inclined to utilize eco-friendly machining processes that can also reduce waste.

In conclusion, selecting the right materials for CNC machining large parts involves a robust understanding of material properties, application requirements, cost-efficiency, and a deep dive into the machining processes. The ability to make informed decisions in choosing materials can greatly enhance machining efficiency, reduce production times, and improve final product quality.

As the manufacturing landscape continues to evolve with technological advancements, staying informed about emerging trends and innovations will further empower businesses to optimize their CNC machining processes. Therefore, investing time and resources in material selection is not just an operational necessity; it is a strategic approach to achieving competitive advantage in a rapidly changing industry.

Evaluating your machining materials and techniques may just be the key to unlocking greater efficiency and quality for your CNC projects. Make it a priority to reflect on these pointers and adapt your strategies accordingly to ensure continued success.