When it comes to CNC machining, the choice of material plays a pivotal role in determining not just the quality of the final product, but also the machining costs involved. Did you know that the type of aluminum alloy selected for machining can lead to cost fluctuations of up to 30%? This stark reality prompts the question: how does the cost of CNC machining for 2024 aluminum compare with that of other aluminum alloys?

In this blog, we will offer an in-depth analysis of CNC machining costs, focusing specifically on 2024 aluminum alloy. We will explore cost factors, compare it with other aluminum alloys, and provide valuable insights for manufacturers and decision-makers in industries that rely on CNC machining.

Understanding 2024 Aluminum Alloy

Properties and Applications

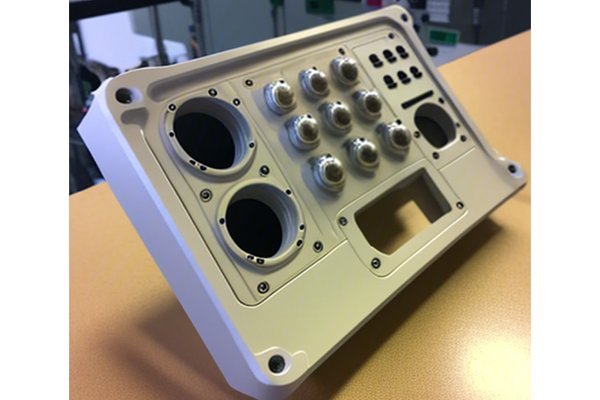

2024 aluminum alloy is widely recognized for its excellent mechanical properties and high strength-to-weight ratio. Commonly deployed in aerospace and military applications, this alloy exhibits great fatigue resistance, making it a preferred choice for aircraft structures and components. However, the inherent characteristics that make it favorable also play a critical role in determining its machining costs.

Comparison with Other Aluminum Alloys

To appreciate the CNC machining costs associated with 2024 aluminum, it is essential to understand how it stacks up against some other widely used aluminum alloys, such as 6061 and

Each alloy’s specific traits will dictate how efficiently it can be machined, directly impacting costs.

Key Factors Affecting CNC Machining Costs

Material Costs

The initial cost of aluminum alloys varies significantly. Generally, 2024 aluminum tends to be more expensive than both 6061 and 7075 due to its alloying elements (primarily copper) and its position in the aerospace market. This initial cost will cascade down to affect the machining cost.

Machining Difficulty

Machining difficulty is influenced by the physical and mechanical properties of the alloy. The higher yield strengths and harder nature of 2024 aluminum make it more difficult to cut and require specialized tooling. This adds to labor and equipment wear costs. Conversely, 6061 aluminum is easier to cut, allowing for faster production rates.

Tooling and Equipment

The types of tools required for machining various aluminum alloys also impact costs. When machining 2024 aluminum, carbide tools are often recommended due to their toughness and resistance to wear. While these tools have a higher upfront cost, they can provide cost savings in the long run by reducing tool change times and leading to higher production efficiency.

Surface Treatment Needs

Post-machining surface treatments can also affect overall costs. 2024 aluminum often requires additional treatments like anodizing or other protective coatings to enhance its corrosion resistance, especially in aerospace applications. This adds another layer to the overall machining expense compared to alloys that require less stringent post-treatment processing.

Production Speed

Production speed is vital in CNC machining. The efficiency with which a part can be machined directly correlates to its cost. Factors such as feed rates, cutting speeds, and tool path strategies play a role. Higher machining speeds can significantly decrease operational costs, but the harder nature of 2024 aluminum means it may not reach the same efficient feed rates as 6061 aluminum.

Detailed Cost Examination

To formulate a clearer perspective, let’s break down hypothetical cost scenarios for machining 2024 aluminum versus 6061 aluminum.

Example Machine Cost Analysis

Imagine a hypothetical project requiring a batch of components with similar geometric complexity made from either 2024 aluminum or 6061 aluminum. Below is a simplified cost breakdown of machining one unit of each:

Machining Costs Per Unit

Summary of Findings

Through the calculations presented, we can discern that the total cost of machining a unit out of 2024 aluminum can significantly exceed that of machining the same unit from 6061 aluminum. This points to a crucial consideration for manufacturers: while 2024 aluminum offers superior strength and fatigue resistance, the associated machining costs may not always justify its use unless the application strictly demands its properties, as in aerospace components.

: Weighing Material Choices for CNC Machining

In the dynamic realm of CNC machining, understanding the nuances of material selection can lead to smarter business decisions. While 2024 aluminum shines in certain applications due to its strength and fatigue life, the cost associated with machining it requires detailed consideration. Factors such as tooling, labor, and production speed must be balanced against the material’s performance benefits.

By leveraging this knowledge, engineers and manufacturers can make informed choices that not only meet project specifications but also deliver cost-effective solutions. In a world where margins can be tight, understanding how different aluminum alloys impact CNC machining costs is not just beneficial—it’s essential. Keep these considerations in mind as you navigate your manufacturing pathways, ensuring that both quality and economic viability remain steadfast in your journey toward excellence in production.