Did you know that the precision in CNC (Computer Numerical Control) machining can significantly impact the quality and performance of the final product? In industries ranging from aerospace to medical technology, understanding material-specific machining techniques can be the difference between a mediocre product and a market leader. In this blog, we will dive deep into the nuances of CNC turning when processing two popular types of stainless steel: 420 and

to CNC Machining

CNC machining is an automated manufacturing process that uses computerized controls to manipulate tools and machinery. It’s widely favored for its high precision and repeatability, making it ideal for companies that require intricate designs and tight tolerances.

Among the various materials that can be machined, stainless steels stand out—particularly grades like 420 and 304 due to their unique properties. Understanding these properties helps manufacturers make informed decisions about their production processes, ensuring optimal quality and performance.

Properties of 420 Stainless Steel

420 stainless steel is a martensitic steel that offers a unique combination of hardness and corrosion resistance. It is particularly known for:

Properties of 304 Stainless Steel

304 stainless steel, on the other hand, is an austenitic steel that boasts excellent corrosion resistance and formability. Its key features include:

CNC Turning: A Comparative Analysis

When considering CNC turning between 420 and 304 stainless steel, several factors come into play. The CNC turning process involves feed rate, cutting speed, tooling selection, and coolant management. Each of these factors can be significantly affected by the material’s properties.

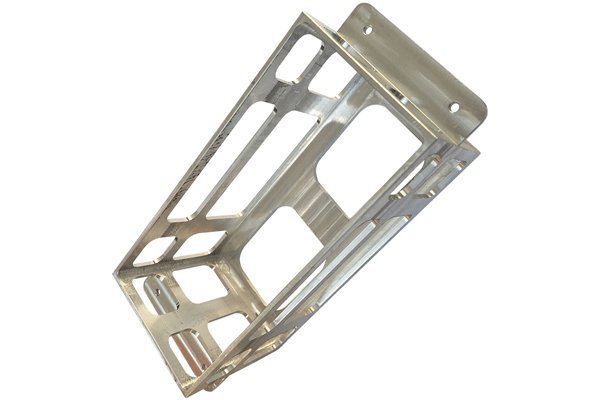

Common Applications

Both types of stainless steel have distinct applications:

Understanding the differences in CNC turning precision between 420 stainless steel and 304 stainless steel goes beyond simply choosing one material over another. It involves a comprehensive grasp of each material’s unique properties and how they influence manufacturing processes such as machining speeds, feeds, tooling, and cooling methods.

This knowledge becomes crucial for industries that require high-strength components with specific performance characteristics. Whether you’re in the automotive, aerospace, or medical field, selecting the appropriate material and machining parameters is vital for producing quality products—leading to enhanced durability, lower costs, and improved operational efficiencies.

In summary, differential precision in CNC turning can significantly impact product outcomes. As technology continues to evolve, understanding material dynamics will be a core competency for manufacturers pursuing excellence and competitiveness in their markets.

This exploration of the differences between 420 and 304 stainless steel reflects the broader importance of making informed decisions, enhancing both product quality and production efficiency. As you reflect on this information, consider how material selection impacts your production processes and outcomes in your industry.