Did you know that the global CNC machining market is projected to reach $100 billion by 2025? This staggering statistic highlights the growing significance of CNC machining technology in various sectors, including manufacturing, automotive, and electronics. One key area where CNC machining stands out is in the production of custom plastic connectors. In this blog, we will explore the numerous benefits of CNC machining for custom plastic connectors, dive into the processes involved, and discuss how industries can take advantage of this technology for optimized production quality and efficiency.

—

The Rise of CNC Machining

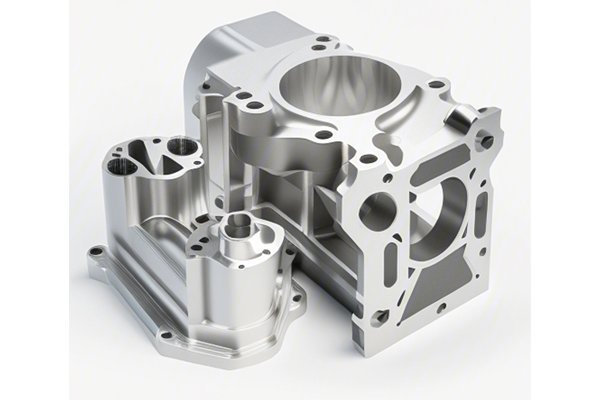

Computer Numerical Control (CNC) machining is a sophisticated process that automates the machining of materials through programmed computer software. This process allows for incredible precision and efficiency, rendering it an essential tool in modern manufacturing.

What Are Plastic Connectors?

Plastic connectors are versatile components that play an integral role in creating electrical circuits, establishing connections between devices, or fastening components together in various applications. Found in everything from consumer electronics to automotive systems, the demand for high-quality, custom plastic connectors is on the rise as industries look for tailored solutions.

—

Understanding CNC Machining for Plastic Connectors

CNC machining for custom plastic connectors involves several stages, from design and prototyping to production and finishing. Here’s a detailed look at the process:

The first step in creating a custom plastic connector is developing a Computer-Aided Design (CAD) model. This digital blueprint allows engineers to visualize the final product and ensure that all specifications are met.

Choosing the right plastic resin is crucial for the function and durability of the connector. Common materials used in CNC machining include:

Once the design and materials are settled, the CNC machining process begins. Key stages include:

After machining, custom plastic connectors often require additional post-processing, such as:

—

The Benefits of CNC Machining for Custom Plastic Connectors

CNC machining offers numerous advantages when it comes to producing custom plastic connectors:

CNC machines produce components with accuracy levels often exceeding 0.01 mm. This precision ensures that connectors fit perfectly in assemblies and perform their intended functions effectively.

Although the initial setup for CNC machining may be higher, the long-term cost savings are substantial due to reduced material waste, faster production times, and minimized labor costs.

With CNC machining, manufacturers can easily adapt designs to meet specific needs without lengthy retooling processes. This flexibility is vital for businesses that require customized solutions.

CNC machining is highly scalable, making it easy to increase production volumes without compromising quality. Whether producing a small batch of prototypes or a large order of thousands of units, CNC machining remains efficient.

CNC machining works with a wide array of materials, allowing manufacturers to choose the most suitable plastic resins for their specific needs. This variety ensures that designers can select materials based on mechanical properties, aesthetics, or cost.

Since CNC machines are programmed to replicate the same processes, they produce consistent output quality, which is essential for products like plastic connectors that require uniformity.

The efficiency of CNC machining means shorter lead times from design to finished product. Businesses can respond quickly to market demands and make updates to their connector designs without significant downtime.

—

Industries that Benefit from CNC Machining of Plastic Connectors

The applications of CNC-machined plastic connectors spread across various industries, each benefiting in unique ways:

In automotive manufacturing, custom plastic connectors are utilized in wiring harnesses, sensor connections, and electronic applications. CNC machining ensures that these components can withstand environmental stresses while maintaining reliability.

The rapid advancement in consumer electronics means that custom plastic connectors must keep pace with compact designs and intricate assembly processes. CNC machining provides the precision needed for complex electronic components.

Medical devices require plastic connectors that are sterile, reliable, and often designed for limited space. CNC machining allows for the production of specialized connectors that meet stringent regulatory guidelines.

Aerospace applications demand connectors that can withstand extreme conditions. CNC machining enables the production of lightweight yet durable plastic connectors that meet the industry’s rigorous standards.

In telecommunications, custom connectors are vital for ensuring signal integrity and connectivity. CNC machining allows for the production of connectors that fit seamlessly into complex systems.

—

Overcoming Challenges in CNC Machining for Plastic Connectors

While CNC machining offers numerous advantages, challenges can arise in the process. Here are some common challenges and solutions:

Some plastic materials may warp during machining, leading to inaccuracies.

CNC machining can lead to rapid tool wear, resulting in diminished accuracy over time.

Highly intricate designs may pose challenges in the machining process.

—

Future Trends in CNC Machining for Plastic Connectors

The future of CNC machining for custom plastic connectors looks promising, with trends poised to reshape the industry:

Advancements in automation technology will continue to streamline CNC machining processes, enhancing efficiency and reducing costs.

The adoption of Industry 4.0 principles will foster real-time monitoring, predictive maintenance, and data analytics, leading to improved decision-making and operational efficiency.

The convergence of CNC machining and 3D printing will allow for more innovative connector designs that leverage the strengths of both processes.

As sustainability trends grow, CNC machining is expected to incorporate eco-friendly materials and practices, reducing waste and lowering energy consumption.

—

In summary, CNC machining for custom plastic connectors provides significant benefits across various industries. Its precision, cost-effectiveness, flexibility, and scalability make it an essential tool for manufacturers seeking to innovate and enhance their product offerings. As industries continue to evolve and adapt to new technologies, CNC machining will remain a key player in delivering high-quality, reliable products tailored to specific needs.

Understanding and leveraging the benefits of CNC machining can provide businesses with a competitive edge in a rapidly changing marketplace. As such, companies should consider integrating this technology into their production processes to ensure they remain at the forefront of their respective industries. The era of custom plastic connectors is here, and the opportunities made possible through CNC machining are boundless. Remember, investing in this technology is investing in efficiency, quality, and future growth.