:

Did you know that according to a report by MarketsandMarkets, the global CNC machining market is expected to grow from $63.45 billion in 2020 to $100.79 billion by 2026? This rapid growth can largely be attributed to the increasing demand for precision engineering components across key industries like aerospace, automotive, and medical. As businesses seek to streamline their manufacturing processes while ensuring high-quality output, CNC (Computer Numerical Control) milling and turning online services have emerged as a solution worth exploring.

If you’re a business owner or an engineer looking for efficient, cost-effective, and precise manufacturing options, this blog will delve deep into the advantages of using CNC milling and turning services for custom parts. We’ll illuminate the various aspects of CNC technologies and how they can optimize your production needs, ultimately leading to enhanced operational effectiveness.

—

Understanding CNC Milling and Turning

Before we dive into the benefits of CNC milling and turning services, it’s essential to clarify what these processes entail.

What is CNC Milling?

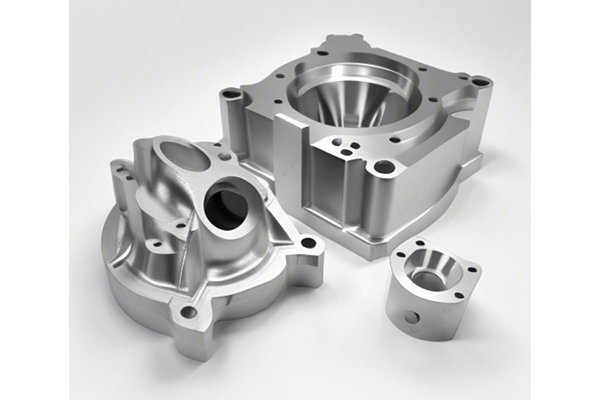

CNC milling is a subtractive manufacturing process that involves the removal of material from a workpiece using rotary cutters. The CNC mill follows pre-programmed computer software to ensure precision and accuracy. These machines can perform a wide array of functions — everything from drilling and cutting to shaping complex designs.

Benefits of CNC Milling:

What is CNC Turning?

CNC turning is another subtractive manufacturing process where a workpiece is rotated on a spindle while a cutting tool removes material from it. This technique shapes cylindrical objects and is widely used for making parts like axles, shafts, and cylindrical fittings.

Benefits of CNC Turning:

—

Why Choose Online CNC Milling and Turning Services?

Now that we understand what CNC milling and turning are let’s explore why opting for online services can be a game-changer.

Online CNC service providers often have a diverse and international team of engineers and machinists, skilled in various manufacturing processes. This diversification allows companies to leverage expert advice and solutions that might not be available locally.

Utilizing online CNC services can lead to significant cost savings. By outsourcing manufacturing, companies eliminate overhead costs associated with maintaining in-house machinery. Moreover, bulk orders often yield discounts, providing an economical route to production.

The online nature of these services dramatically enhances the ability to prototype quickly. Designs can be submitted digitally, and, in response, manufacturers can create initial prototypes swiftly. This accelerated process reduces time-to-market for new products considerably.

Online CNC services offer a seamless experience from design to delivery. With user-friendly interfaces and instant-quotes systems, clients can receive immediate feedback on price and delivery times. This streamlining means that businesses can focus more on their core operations rather than getting bogged down by logistics.

Many online CNC service providers invest in the latest machinery and technology. This means clients benefit from cutting-edge equipment without needing to invest heavily in machinery themselves. Furthermore, advancements in technology allow for continuous improvements in production quality and turnaround times.

—

The Step-by-Step Process of Getting Custom Parts Online

If you’re considering using online CNC milling and turning services, here are the essential steps you’ll typically follow:

Step 1: Design Your Part

Begin with a detailed design of your part. Most online services accept various formats like CAD (Computer-Aided Design) files. Ensure that your designs are accurate, as this will directly impact the final product.

Step 2: Choose Your Material

With CNC machining, the choice of material is vital. Aluminum, steel, titanium, and various plastics are common options. Consider the functional requirements of your part, as different materials will yield different performance characteristics.

Step 3: Submit a Quote Request

Once you’ve prepared your design and chosen your materials, submit your files to the online service for an immediate quote. This process should provide valuable information regarding cost and lead time.

Step 4: Review and Approve the Quote

Review the quoted design thoroughly, including the pricing, materials, and lead times. Make any necessary adjustments and approve the quote to move forward in the production process.

Step 5: Production Begins

Upon approval, your part will enter production. Most online services will notify you of their progress and estimated completion times.

Step 6: Quality Assurance

Once completed, parts undergo quality checks to ensure they meet your specifications. This critical step mitigates the risk of defects and ensures you receive a reliable product.

Step 7: Shipping

Once quality assurance is complete, the parts are packaged and shipped to you. Good online services often offer multiple shipping options to suit your demands.

—

Key Considerations When Choosing an Online CNC Service

While finding the right service can save you time and money, it’s crucial to evaluate potential providers carefully. Here are some things to consider before making a decision:

Research the service provider’s reputation. Client testimonials and ratings can provide invaluable insights into the quality of their work and overall customer service.

Inquire about the technology and machinery they use. Advanced equipment enhances the accuracy and quality of produced parts.

Ensure that the online service offers the materials you require. A more extensive selection allows for more flexibility in your designs.

Understand the production lead time for your parts. Timeliness is often a critical factor, particularly when working on tight schedules.

Reliable customer support can make or break your experience with an online service. Look for companies that prioritize communication and are available to answer any questions throughout the process.

—

The Future of CNC Milling and Turning Online Services

As technology continues to evolve, CNC machining is becoming even more sophisticated. The integration of artificial intelligence (AI), the Internet of Things (IoT), and smart manufacturing solutions are shaping the future of CNC services.

By staying ahead of these developments, businesses can continue to improve their manufacturing processes, ensuring they remain competitive in the fast-evolving market.

—

In conclusion, CNC milling and turning online services offer numerous advantages for businesses looking to produce custom parts efficiently and economically. These services provide access to advanced technology, global expertise, cost-effectiveness, rapid prototyping, and streamlined processes.

By understanding the complete process from design to delivery and carefully choosing a reputable online provider, companies can optimize their production capabilities while minimizing costs.

The insights shared in this blog are critical for anyone considering custom machining solutions—they highlight the efficiency and effectiveness of CNC technologies available today. Embracing online CNC milling and turning services could be a transformative step for your business, fostering innovation while keeping pace with industry demands.

Remember, investing time in understanding these processes will pay off as you seek to refine your production strategies and stay ahead of the competition.