Did you know that CNC machining has transformed the manufacturing landscape, with over 4 million CNC machines utilized in various industries worldwide? This impressive number reflects the growing reliance on CNC technology for creating precise and durable components that meet the increasing demands of engineering projects. As industries evolve, so do the challenges faced in producing high-quality parts. How can CNC machining help ensure that your engineering projects are not only efficient but also durable?

In this extensive blog, we will delve into the myriad benefits of employing CNC machining for producing durable parts in engineering projects. We will explore how CNC technology minimizes errors, optimizes production processes, and enhances the overall quality of engineering components. By the end of this blog, you will have a comprehensive understanding of how CNC machining transforms engineering processes, the various methods employed, and the best practices to leverage its advantages.

Understanding CNC Machining

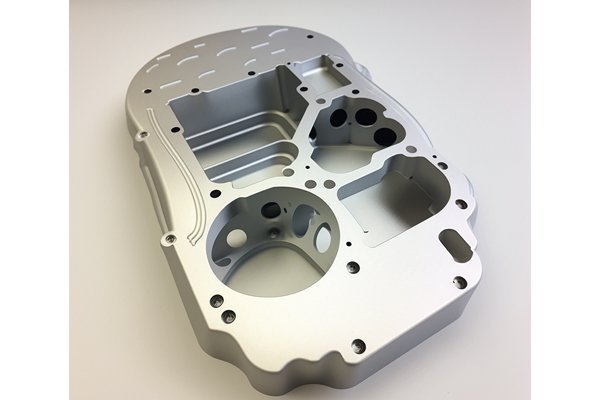

Before diving deep into the benefits, it’s essential to grasp the concept of CNC (Computer Numerical Control) machining. CNC machining is a manufacturing process that utilizes computer-controlled machines to cut, shape, and mold various materials, such as metals, plastics, and composites. This technology allows for the production of intricate parts with high precision and repeatability, making it an indispensable asset in engineering projects.

Types of CNC Machining Processes

Why CNC Machining?

As engineering projects become more complex and intricate, traditional manufacturing methods struggle to keep up with the demand for precision, speed, and consistency. CNC machining addresses these challenges by offering several key benefits:

Benefits of CNC Machining for Durable Parts

One of the standout benefits of CNC machining is its ability to produce parts with remarkable precision. The inherent nature of CNC technology allows for a degree of accuracy that is difficult to achieve manually. Computer-controlled processes eliminate human error, ensuring that parts are produced according to exact specifications. Whether it’s a simple geometric shape or a complex assembly, CNC machining delivers consistency across batches, vital for any engineering project requiring durability.

In engineering, the durability of components is paramount. CNC machining significantly enhances the durability of parts by providing tighter tolerances and uniform surface finishes. Materials can be precisely shaped and treated to withstand high-stress conditions. Processes such as heat treatment, surface hardening, and anodizing can be integrated into CNC machining operations to further enhance material properties, extending the lifespan of the produced components.

Time is money in engineering projects, making speed a critical factor. CNC machining can significantly reduce production times compared to traditional methods. The automation of the machining process allows for rapid production without sacrificing quality. Moreover, CNC machines can operate continuously, enabling increased output and reduced lead times, making them suitable for mass production of durable parts.

CNC machines are incredibly versatile, capable of handling various materials and accommodating different manufacturing requirements. Whether you need components made from metals, plastics, ceramics, or composites, CNC machining can adapt to the specific needs of your project. This versatility allows engineers to experiment with materials and designs, creating innovative solutions that stand out in the marketplace.

While the initial investment in CNC machinery can be significant, the long-term benefits far outweigh the costs. The efficiency, precision, and durability of CNC-machined parts can lead to significant cost savings over time. Reduced material waste, faster production cycles, and decreased labor costs contribute to a more economical manufacturing process. Moreover, due to their high quality and durability, CNC parts often require less maintenance and replacement, optimizing operational budgets further.

Engineering components often require complex designs that are difficult to achieve with manual machining. CNC machining is highly adept at producing intricate geometries that would be nearly impossible or extremely labor-intensive to create otherwise. This ability to create complex parts opens up new design possibilities, enabling engineers to develop cutting-edge products while maintaining durability standards.

CNC machining is quickly becoming more integrated with Industry 4.0 technologies. The rise of smart factories has led to automation and data exchange across manufacturing processes. CNC machines can be programmed to collect real-time data on production metrics, leading to improved quality control and reduced operational errors. Engineers can monitor processes remotely, optimizing their workflows while ensuring the production of durable parts at every stage.

In engineering, tolerances are crucial to the functionality of components. CNC machining excels at meeting low tolerance specifications due to its precision and repeatability. A slight deviation in dimensions can lead to failure in systems or components designed to work together. CNC’s ability to consistently produce parts that adhere to strict dimensional tolerances is vital for ensuring the performance and durability of engineering solutions.

How CNC Machining Meets Engineering Challenges

Addressing Material Selection

Selecting the right material for durable parts is crucial in engineering. Each material has its unique properties, strengths, and weaknesses. CNC machining allows for precise shaping of various materials, ensuring that engineers can select the most suitable option for their specific application. Common materials utilized in CNC machining include:

Designing for Manufacturability

CNC machining technology can greatly influence the design process for engineering components. Engineers can collaborate with CNC machinists to optimize designs for manufacturability by eliminating unnecessary complexities and ensuring designs are compatible with CNC processes. This not only improves the efficiency of the production process but also enhances part durability by reducing stress concentrations and potential failure points.

Integrating Prototyping and Production

CNC machining is invaluable in the prototyping phase of engineering projects. The ability to create quick prototypes allows engineers to test and iterate designs before moving into full-scale production. This integration of prototyping and production capabilities accelerates the development process, enabling teams to identify and rectify issues early on, ensuring that the final product is durable and effective.

Best Practices for Using CNC Machining in Engineering Projects

To fully harness the benefits of CNC machining for durable parts, it is crucial to adopt best practices throughout the design and production processes:

Before incorporating CNC technology into a project, spend ample time on planning and developing comprehensive designs. Create 3D models and simulations to visualize the final product and determine potential challenges.

Establish clear tolerances for each component to ensure that they meet the required specifications. Collaborate with machinists to understand the capabilities and limitations of CNC machines and adjust tolerances accordingly.

To ensure consistent quality and performance, implement a regular maintenance schedule for CNC machines. Lubrication, calibration, and routine checks can prevent unforeseen breakdowns and ensure that parts are produced with precision.

Investing in high-quality raw materials is paramount for durable parts. Avoid using low-grade materials that may compromise the integrity and performance of the final components.

As technology continues to evolve, remain open to learning about new advancements in CNC machining techniques and technologies. Engaging in continuous education will enable you to leverage the latest best practices and innovations to maintain a competitive edge in manufacturing processes.

CNC machining has revolutionized the way engineers approach durable parts production, providing them with precise, efficient, and cost-effective solutions. As we have explored throughout this blog, the benefits of CNC machining encompass enhanced precision, durability, speed, flexibility, and overall quality.

Understanding and utilizing CNC machining are crucial for engineers aiming to excel in today’s competitive landscape. By leveraging its capabilities, not only can you produce high-quality components, but you can also address the challenges and demands of modern engineering projects.

As industries continue to advance and evolve, the importance of CNC machining only grows. By embracing this technology, engineering professionals can ensure that their projects are not only successful but also set the stage for innovation and durability in the future. The world of engineering is ever-changing—it’s time to consider whether CNC machining can take your engineering projects to the next level.