: The Rise of Precision Manufacturing

Did you know that the global CNC machining market is projected to reach $100 billion by 2026, driven mainly by industries demanding higher precision and faster production rates? As manufacturing becomes ever more competitive, companies are on the lookout for technologies that can help them produce parts with flawless accuracy while also maximizing productivity. Enter the 5-axis vertical machining center—a game changer in precision part manufacturing.

The transition from traditional 3-axis machining to a 5-axis configuration might seem daunting, but the benefits can significantly outweigh the initial learning curve and investment. This blog aims to elucidate the advantages of utilizing a 5-axis vertical machining center for precision parts production, offering insights into how this technology can elevate the efficiency, accuracy, and capabilities of modern manufacturing processes.

Chapter 1: Understanding 5-Axis Machining

1.1 What is 5-Axis Machining?

At its core, 5-axis machining refers to a method that allows the cutting tool to move in five different axes simultaneously. Unlike traditional 3-axis machining, which can only move along the X, Y, and Z axes, a 5-axis machine adds rotation around the X and Y axes, allowing for intricate and complex geometries to be produced with greater ease and efficiency.

1.2 How Does a 5-Axis Machining Center Work?

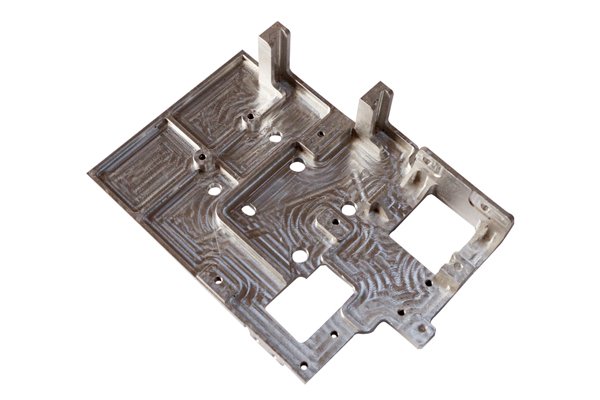

In a 5-axis vertical machining center, the workpiece is securely clamped to a table that can rotate and tilt. Additionally, the cutting tool can approach the workpiece from multiple angles. This multi-dimensional approach allows for more intricate designs to be manufactured in a single setup, greatly reducing the need for multiple machine setups, fixturing, and lengthy adjustments.

Chapter 2: Benefits of 5-Axis Vertical Machining

2.1 Enhanced Precision and Accuracy

One of the standout advantages of 5-axis machining is its capacity to produce highly precise parts. It minimizes errors caused by tool wear, misalignment, and other factors. The ability to machine complex contours in a single setup reduces the chance of inaccuracies, leading to a tighter tolerance in finished products.

2.2 Improved Surface Finish

The advanced control over the tool’s angle and position allows for better cutting efficiency and fewer vibrations, resulting in an improved surface finish. This is particularly beneficial in industries such as aerospace and medical, where surface integrity is critical.

2.3 Shorter Lead Times

5-axis machining can drastically reduce lead times. By allowing multiple operations to be performed simultaneously, manufacturers can produce parts faster. This is especially helpful in high-volume production settings, where time is often a crucial factor.

2.4 Versatility

Another major advantage is versatility. A 5-axis vertical machining center can handle a diverse range of materials, from soft plastics to hard metals like titanium and superalloys. This adaptability enables manufacturers to be more agile, accommodating a broad spectrum of projects and client requirements.

2.5 Cost Efficiency Over Time

Though the initial cost of a 5-axis machine might be higher, the long-term savings can be substantial. Reduced need for multiple setups, less downtime, and lower scrap rates all contribute to a more efficient production environment, making it financially advantageous over time.

Chapter 3: Applications of 5-Axis Machining in Various Industries

3.1 Aerospace Industry

The aerospace sector often demands parts with complex geometries and stringent tolerances. 5-axis machining meets these demands, enabling the manufacture of components like turbine blades and airframe structures that are both lightweight and durable.

3.2 Medical Equipment

In the medical field, precision is paramount. Surgical instruments, implants, and prosthetics require meticulous design and accuracy. The 5-axis vertical machining center facilitates the production of these complex parts, ensuring high quality while meeting regulatory standards.

3.3 Automotive Industry

For the automotive sector, 5-axis machining enables rapid prototyping and the manufacturing of complex components, such as engine parts and custom enclosures. This technology allows for innovative designs that enhance performance and efficiency.

3.4 Energy Sector

In renewable energy, particularly in wind and solar technology, the need for lightweight yet durable components is essential. 5-axis machining allows manufacturers to create these intricate parts without compromising their structural integrity.

Chapter 4: Transitioning to 5-Axis Machining

4.1 Assessing Your Manufacturing Needs

Before making the transition, it is crucial to assess your current manufacturing processes. Determine the types of parts you produce and identify whether 5-axis machining could streamline or enhance any specific processes.

4.2 Training Your Workforce

Transitioning to a 5-axis vertical machining center will require proper training for your operators and engineers. Investing in educational resources and workshops can help smooth the learning curve associated with this advanced technology.

4.3 Upgrading Equipment

Consider evaluating your existing equipment. Upgrading to a 5-axis machine may necessitate a significant investment, but it’s important to view this as a long-term investment that can yield substantial returns through enhanced productivity and efficiency.

Chapter 5: Choosing the Right 5-Axis Machining Center

5.1 Assess Your Requirements

Identify your specific needs: material types, production volume, available space, and budget are all crucial factors that will influence your choice.

5.2 Research and Compare Models

Conduct thorough research on available models in the market, focusing on manufacturers known for reliability and innovation in the CNC machining industry. Compare specifications and functionalities to find the best fit for your needs.

5.3 Consider After-Sales Support

Evaluate the after-sales support offered by the equipment manufacturer. Reliable technical support and accessible service can significantly reduce downtime and improve machine performance.

: Embracing the Future of Manufacturing

The integration of a 5-axis vertical machining center in precision part manufacturing represents much more than just an equipment upgrade; it symbolizes a shift towards efficiency, accuracy, and innovation. As industries evolve and consumer demands increase, having the capability to produce complex parts swiftly and with precision becomes invaluable.

In this blog, we’ve explored the transformative potential of 5-axis machining, from its fundamental concepts and benefits to its various applications across multiple industries. Transitioning to this advanced machining method may require an investment in time and resources, but the long-term advantages far outweigh the initial obstacles.

As we look toward the future of manufacturing, being ahead of the curve is no longer optional—it’s essential. If you want to remain competitive in your industry, considering the adoption of a 5-axis vertical machining center is a step worth taking. The ongoing evolution in precision machining technology is an exciting space to watch, and embracing these advancements will undoubtedly shape the future of manufacturing for years to come.