Did you know that the aerospace industry is projected to grow to over $1 trillion by 2030? This staggering figure highlights the increasing demand for high-quality, precision-engineered components to meet the needs of modern aviation. As air travel becomes more accessible, the pressure on manufacturers to produce lightweight, durable, and high-performance parts has never been higher. This is where CNC (Computer Numerical Control) machining shines, particularly for creating custom metal parts tailored for the complexities of aerospace applications.

In this comprehensive blog, we will delve deep into the various advantages that CNC machining offers for custom metal parts within the aerospace sector. From reducing production time to enhancing accuracy and facilitating intricate designs, we will cover it all. So, if you’re curious about how CNC machining can revolutionize aerospace manufacturing, keep reading!

—

Understanding CNC Machining

CNC machining is a sophisticated manufacturing process that utilizes computer-controlled machines to automate the cutting, shaping, and finishing of materials. This method allows manufacturers to achieve extreme precision, often within fractions of a millimeter, which is essential in aerospace applications where even the slightest deviation can lead to catastrophic failures.

CNC machining comes in various forms, including milling, turning, and grinding. Each type serves unique purposes and can be used interchangeably in some cases to achieve optimal results.

—

Benefits of CNC Machining in Aerospace Manufacturing

With a focus on custom metal parts, let’s explore the numerous benefits that CNC machining brings to the aerospace industry:

One primary advantage of CNC machining is its ability to deliver high levels of accuracy consistently. Precision is non-negotiable in aerospace manufacturing; a small error could lead to severe implications. CNC machines operate under a controlled environment, programmed to produce identical components repeatedly, ensuring that every part meets stringent quality standards.

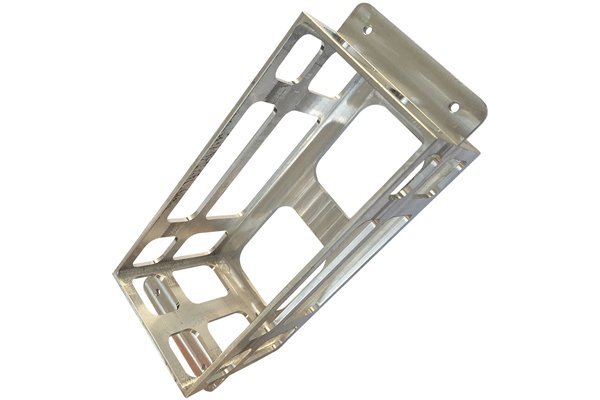

Aerospace components often require intricate designs with complex geometries that traditional manufacturing methods may struggle to achieve. CNC machining allows for high levels of customization, enabling engineers to design and produce parts that may include features like convergent angles, tight tolerances, and complex internal structures.

CNC machining streamlines the manufacturing process. Automated operations reduce the need for manual labor and minimize lead times, enabling manufacturers to produce components faster. This speed is particularly crucial in the aerospace sector, where timely delivery can impact entire project schedules.

While CNC machining might have higher setup costs, it becomes cost-effective for small batch production. When compared to traditional methods that often require extensive tooling, CNC machines can handle multiple setups without extensive adjustment, lowering the cost per unit for smaller production runs.

CNC machining supports a wide range of materials—aluminum, titanium, stainless steel, and even composite materials are commonly used in aerospace applications. The ability to utilize various metals allows manufacturers to choose the best material for specific parts, considering factors such as weight, strength, and thermal resistance.

CNC machines eliminate excess waste with automated cutting paths that optimize the use of raw materials. This is significant in aerospace manufacturing, where the cost of high-quality materials can be substantial. By maximizing yields, CNC machining contributes to sustainable manufacturing practices.

Aerospace manufacturing is heavily regulated. CNC machining helps ensure that all produced components comply with industry regulations by maintaining high-quality standards throughout the production process. This minimizes the risk of defects that could affect aircraft safety.

—

Overcoming Challenges in Aerospace Manufacturing with CNC Machining

While CNC machining comes with numerous advantages, it also faces challenges, particularly in the aerospace sector. Here’s how these challenges can be effectively managed:

CNC machines can be expensive. However, manufacturers can offset this cost by evaluating long-term production needs. Investing in reliable CNC technology can lead to savings in labor, material waste, and production time over time.

CNC machining requires a skilled workforce that can program and operate CNC machines. Investing in training programs ensures that your team is equipped with the necessary skills to maximize machine capability and maintain product quality.

Certain metals can be difficult to machine due to their hardness or toughness. Selecting the right tools and adjusting programs can help manage these limitations, ensuring that the most challenging materials can be worked effectively.

—

Case Studies: Successful Applications of CNC Machining in Aerospace

Boeing has leveraged CNC machining for various components, particularly in producing the aluminum and titanium parts for the 787 Dreamliner. The use of CNC milling and turning has enabled Boeing to achieve precise dimensions and surface finishes, reducing assembly time and improving aerodynamics.

SpaceX employs CNC machining extensively in its rocket components. The company’s focus on rapid prototyping allows them to produce custom parts for the Falcon Heavy and the Starship efficiently, demonstrating how CNC technology supports innovation in space exploration.

Lockheed Martin, a leading aerospace manufacturer, has incorporated CNC machining into the production of their F-35 fighter jet. Through the use of advanced CNC milling, the company has produced critical components that meet aircraft durability and performance standards.

—

In summation, CNC machining offers incredible advantages to the aerospace manufacturing landscape, particularly for custom metal parts. Its ability to enhance precision, reduce production time, and support complex designs is vital in today’s fast-paced manufacturing environment.

As we look to the future, the aerospace industry will continue to evolve, presenting even more challenges and opportunities. The reliance on advanced manufacturing technologies, specifically CNC machining, will be critical in ensuring safety, efficiency, and innovation in aerospace engineering.

As a reminder, the benefits of CNC machining are not limited to aerospace alone but can apply to various sectors where precision and quality are paramount. By understanding and embracing these technologies, manufacturers can position themselves favorably in an increasingly competitive landscape.

Whether you are an aerospace manufacturer seeking to optimize your production capabilities or a newcomer in the industry, the potential of CNC machining presents a frontier of opportunities worth considering. As we continue to push the boundaries of aerospace technology, the importance of quality and precision in manufacturing cannot be overstated.

Related Posts

- Can CNC machining provide precision machining services according to customer-provided drawings and specifications?

- How can CNC machining technology improve production efficiency and product quality in manufacturing processes?

- How Can 5-Axis CNC Machining Services Enhance Accuracy and Efficiency in Part Production?