—

Did you know that, according to a study by Allied Market Research, the global CNC machine market is projected to reach $100 billion by 2024, growing at a compound annual growth rate (CAGR) of 6.5%? This staggering statistic underscores the increasing reliance on CNC (Computer Numerical Control) machining in various industries, such as aerospace, automotive, medical, and manufacturing. But with such a vast array of CNC machining equipment available, how do you choose the right one tailored to your project’s specific requirements?

In this blog, we will delve into key factors that should guide your selection process, shedding light on the critical elements of CNC machining equipment. This comprehensive guide is designed to equip engineers, project managers, and decision-makers with the knowledge needed to make informed choices that will lead to successful project outcomes.

—

Understanding CNC Machining

Before we dive into how to select CNC machining equipment, it’s essential to understand what CNC machining is and why it has become an indispensable tool in modern manufacturing.

What is CNC Machining?

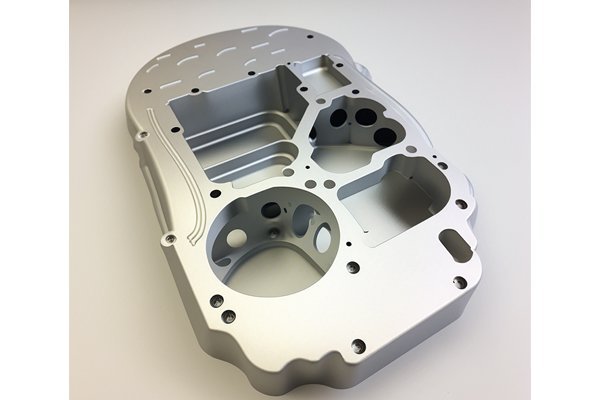

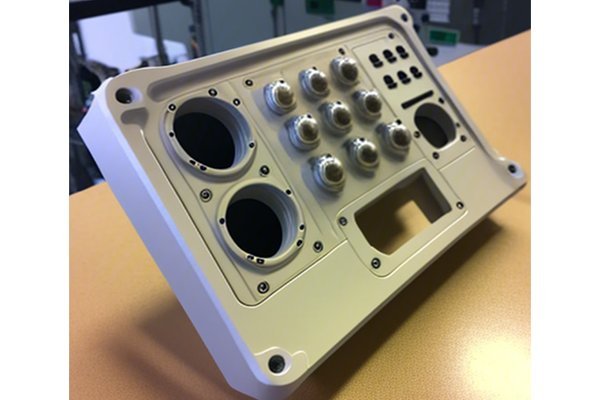

CNC machining is a subtractive manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery. This technology can control a range of complex machinery, including grinders, lathes, and mills. Because of its precision and ability to create intricate designs, CNC machining has become synonymous with high-quality manufacturing.

Benefits of CNC Machining

—

Factors to Consider When Choosing CNC Machining Equipment

When selecting CNC machining equipment, there are various factors to consider that can affect not only production efficiency but also the overall quality of the finished product.

Define Your Objectives: Start with a clear understanding of what your project entails. Are you machining metal, plastic, or composite materials? What are the precision and tolerance requirements? A clear definition of your project’s needs will guide your equipment choices.

Low vs. High Batch Production: Consider whether you will be producing large volumes or custom parts. Some CNC machines are better suited for high-volume production, while others are designed for low-volume, high-mix environments.

Material Type: Different CNC machines are optimized for specific materials. For example, if your project involves machining aluminum, you’d benefit from a machine with good feed rates and optimized tooling for softer metals.

Material Thickness: Ensure the machine you choose can handle the required material thickness. Each machine comes with a specific capacity for different materials, and exceeding those limits could lead to quality issues or equipment damage.

Milling Machines: Best for complex 3D shapes; they remove material from the workpiece using rotary cutters.

Lathes: Ideal for cylindrical parts; they rotate the workpiece against a cutting tool.

Plasma Cutters: Used for metal plates; these machines use plasma to cut through thick materials efficiently.

Laser Cutters: Suitable for intricate designs; they employ high-powered lasers to cut through various materials with precision.

3D Printers: Though not traditional CNC, they form a growing part of CNC technology, allowing for additive manufacturing processes.

Selecting the right type of machine will significantly influence your project’s outcome.

Understanding the required accuracy levels for your project is crucial. Tolerances are often determined by the industry’s standards and the end-use of the components.

The control system of the CNC machine significantly impacts its capabilities. Machining processes can be controlled through G-code, which dictates the movements.

Automation can streamline your operations and minimize the potential for human error. Evaluate whether the CNC machine supports automation for tasks like tool changing, material handling, and load/unload functions.

Evaluating CNC Machines: Checklist

Creating a checklist based on the above factors can simplify and enhance the decision-making process when assessing CNC machines. Here’s a practical evaluation checklist:

—

Cost Considerations

While initial costs are vital, consider the long-term costs associated with maintenance, tooling, and potential upgrades.

Return on Investment (ROI)

Establish a clear ROI from your investment by measuring factors such as reduced labor costs, improved cycle times, and enhanced productivity.

—

Future-Proofing Your Equipment

With technology rapidly evolving, consider how easily the CNC machine can be upgraded or modified in the future. You want to ensure that your investment can adapt to new manufacturing processes and technologies that may arise.

—

Choosing the right CNC machining equipment for your project can be a daunting task given the many options and considerations. However, with a structured approach that encompasses project specifications, material compatibility, equipment type, automation capabilities, and cost considerations, you can make a well-informed decision that enhances production efficiency and product quality.

In conclusion, understanding the intricacies of CNC machining equipment can lead to significant improvements in your manufacturing processes. As the CNC landscape continues to evolve, investing in the right machinery is not just a smart choice—it’s essential for thriving in today’s competitive marketplace.

Reflecting on this guide should inspire you to delve deeper into each aspect and consider how you can leverage the advantages of CNC technology for your projects. This blog serves as both a roadmap and a catalyst for future discussions about the essential role of CNC machining in modern manufacturing—which is undoubtedly worth your consideration!