: A Cutting-Edge Revolution

Did you know that laser cutting has transformed the manufacturing sector with precision and speed that was previously unimaginable? According to a report from Research and Markets, the global laser processing market is projected to reach USD 21.6 billion by 2026, growing at a Compound Annual Growth Rate (CAGR) of 7.2% from

As we delve deeper into the world of CNC laser processing, we will explore its numerous advantages, its broad applications, and the transformative impact it has across various industries. Whether you’re an engineer, a manufacturer, or simply curious about modern machining technologies, this blog will offer you insights that are critical for your understanding and potentially beneficial for your business decisions.

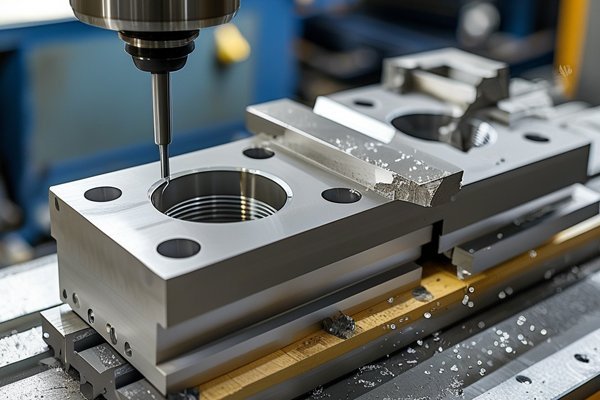

What is CNC Laser Processing?

CNC laser processing refers to the use of CNC machines that employ lasers to cut, engrave, or etch various materials. The process involves directing a laser beam through optics and computer programs to precisely control the cutting path and depth. This technology supports high-quality production while maintaining significant speed and flexibility, making it suitable for both small and large-scale operations.

The Mechanics of CNC Laser Processing

Understanding CNC laser processing begins with its components and operational mechanisms:

Key Advantages of CNC Laser Processing

2.1 Precision and Accuracy

One of the most compelling advantages of CNC laser processing is its unparalleled precision. The laser beam can achieve tolerances as fine as 0.1 mm, leading to high-quality finishes that minimize the need for secondary operations.

2.2 Versatility in Material Processing

CNC laser processing can cut and engrave a variety of materials—from metals (like stainless steel, aluminum, and brass) to non-metals (like wood, acrylic, and leather). This versatility makes it a valuable tool for diverse manufacturing sectors.

2.3 Reduced Material Waste

Traditional cutting methods often generate a significant amount of waste. However, the focused nature of laser cutting permits tighter nesting of parts, resulting in minimal scrap material and cost savings.

2.4 Speed and Efficiency

With CNC laser processing, production times are significantly reduced. The high-speed operation means that manufacturers can produce components rapidly, enabling quicker turnaround times for projects.

2.5 Minimal Heat Affected Zone (HAZ)

Unlike conventional cutting methods that can cause deformation and significant heat buildup, laser cutting produces a narrow heat-affected zone. This results in less warping and thermal distortion, preserving the integrity of the material.

2.6 Automation and Consistency

The CNC system allows for automation, ensuring that each part produced meets the same exact specifications and quality standards. This consistency is invaluable in high-volume production runs.

2.7 Capability for Complex Designs

Intricate designs that would be difficult or impossible to achieve with conventional methods can be easily executed with lasers. This makes CNC laser processing ideal for artistic applications as well as high-tech manufacturing.

Applications of CNC Laser Processing

3.1 Aerospace

In the aerospace industry, precision and weight are critical. CNC laser processing is used to fabricate airframe parts, engine components, and even intricate test fixtures. The ability to work with lightweight materials—essential for flight—enhances performance while maintaining the safety standards required in aviation.

3.2 Automotive

From cutting sheet metal to engraving intricate designs and branding, CNC laser technology is widely employed in automotive manufacturing. It aids in the production of components such as body shells, custom parts, and interior accents, enabling both efficiency and design flexibility.

3.3 Electronics

In the electronics industry, CNC laser processing is utilized for cutting circuit boards, enclosures, and connectors. The precision of laser cutting ensures that components fit together well, which is crucial for the functionality of electronic devices.

3.4 Architecture and Interior Design

CNC laser processing finds application in creating decorative elements, signage, and unique architectural features. This allows architects and designers to bring their visions to life with great detail.

3.5 Medical Device Manufacturing

The medical industry benefits significantly from CNC laser processing’s precision. It is employed in producing surgical instruments, implants, and various medical devices where exact specifications and hygienic standards must be met.

3.6 Arts and Crafts

Artists are increasingly turning to CNC laser processing to create custom designs, art pieces, and signage. This technology allows for the production of unique items that can be personalized for clients.

3.7 Signage Industry

CNC laser processing is widely used in the signage industry for cutting and engraving letters and logos with precision. This capability allows businesses to create customized signage that can withstand outdoor conditions while maintaining aesthetic appeal.

Challenges and Solutions in CNC Laser Processing

Despite its numerous advantages, CNC laser processing is not without challenges. Some common issues faced during implementation include:

4.1 Material Limitations

While CNC laser processing is versatile, some materials (such as certain plastics) may melt or warp under heat. The solution lies in selecting appropriate laser types and optimizing settings for each specific material.

4.2 Initial Investment Costs

Setting up a CNC laser processing system can involve substantial initial costs. However, businesses can mitigate this by conducting a cost-benefit analysis to identify long-term savings in material waste, labor costs, and production time.

4.3 Maintenance Requirements

Like any advanced machinery, CNC laser systems require regular maintenance to perform optimally. Manufacturers need to develop a robust maintenance schedule and training programs for technicians to ensure machinery remains in top condition.

Future Trends in CNC Laser Processing

As technology advances, we can expect several exciting trends in CNC laser processing:

5.1 Increased Integration with AI and IoT

The integration of Artificial Intelligence (AI) and the Internet of Things (IoT) into CNC systems could lead to smarter operations. Predictive maintenance, automated adjustments, and enhanced efficiency could significantly improve production metrics.

5.2 Sustainable Practices

With a growing emphasis on sustainability, manufacturers are investigating how CNC laser processing can align with eco-friendly practices—such as using renewable materials and optimizing energy consumption.

5.3 Advancements in Laser Technology

Improvements in laser technology (like higher-powered lasers and better beam quality) will allow machines to cut through thicker and more difficult materials while maintaining precision.

: Embracing the Future of Manufacutring

In summary, CNC laser processing represents a remarkable blend of precision, versatility, and efficiency that has redefined modern manufacturing. Businesses leveraging this technology can create high-quality products while optimizing costs and minimizing material waste. From aerospace to electronics, the applications of CNC laser processing continue to expand, ushering in a new era of design possibilities.

As we advance into the future of manufacturing, understanding the capabilities and advantages of CNC laser processing will not only keep businesses competitive but also drive innovation within their respective industries. Embracing this technology is paramount for anyone looking to thrive in a rapidly-evolving market.

Thus, the discussion around CNC laser processing offers valuable insights that are worth considering. The technology is not simply a tool; it serves as a gateway to innovation, efficiency, and sustainable practices in manufacturing that will shape the future landscape of numerous industries. Remember, staying informed about these advancements could be the key to unlocking the full potential of your operations.

Related Posts

- How Does the Material Selection for CNC Prototypes Impact Their Recyclability and Sustainability?

- What Are the Advantages of CNC Machining for Lightweight Aluminum Automotive Components?

- What is the difference in wear resistance and mechanical properties between C260 brass and C36000 brass in CNC turning?