Did you know that nearly 50% of product development time can be reduced by using rapid prototyping techniques? In an era where speed and efficiency dominate market competition, the ability to create and test prototypes quickly has become a game changer for businesses across a multitude of industries. Rapid prototyping empowers inventors, engineers, and designers to visualize their ideas, make adjustments, and ultimately launch successful products faster than ever before.

In this comprehensive blog post, we will delve deep into the world of rapid prototyping: exploring its processes, types, and unrivaled advantages. Whether you are a product manager, engineer, or just an enthusiast eager to learn more about this innovative approach to product development, you are in the right place.

What is Rapid Prototyping?

Rapid prototyping refers to a set of techniques used to quickly fabricate a scale model of a physical part or assembly using three-dimensional computer-aided design (CAD) data. It allows creators to visualize their concepts early in the design phase, facilitating the testing and evaluation of ideas before they move into the production stage.

The primary goal of rapid prototyping is to minimize time and reduce costs while maximizing efficiency in product development. By enabling rapid iteration and frequent user testing, businesses can better meet customer needs and expectations.

The Importance of Rapid Prototyping in Modern Manufacturing

2.1 Accelerated Time to Market

One of the primary advantages of rapid prototyping is its ability to significantly accelerate the time to market for new products. In the fast-paced landscape of modern business, being able to prototype and test concepts quickly can mean the difference between a successful launch and missed opportunities. By getting products into the hands of consumers earlier, companies can gather feedback and make improvements before full-scale production begins.

2.2 Cost Efficiency

Building a physical model traditionally involves considerable time and financial investment. Rapid prototyping, on the other hand, offers cost savings through reduced labor, decreased material usage, and minimized risk of failure during production. Companies can validate their designs before overspending on extensive tooling and manufacture processes.

2.3 Improved Product Quality

Rapid prototyping allows for continuous improvement. Designers can experiment, refine, and iterate their products based on actual performance data collected from prototype testing. This iterative process leads to high-quality final products that are more aligned with user needs and market demands.

2.4 Enhanced Collaboration and Communication

Rapid prototypes bridge the communication gap between teams. Visual representations of concepts improve collaboration among designers, engineers, and marketing teams. Clear visual models facilitate discussions about function, form, and design, resulting in more coherent and focused product development.

Processes of Rapid Prototyping

Understanding the processes involved in rapid prototyping is critical for harnessing its advantages effectively. The following sections will explore common processes used in rapid prototyping.

3.1 3D Printing (Additive Manufacturing)

3D printing is perhaps the most renowned method of rapid prototyping. This additive manufacturing technique involves creating objects layer by layer from 3D CAD models. Several types of 3D printing technology exist, including:

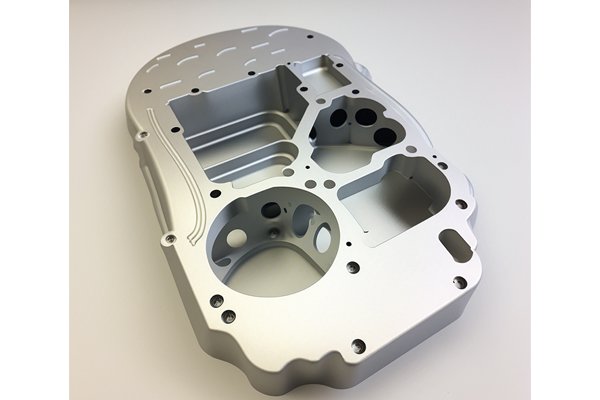

3.2 CNC Machining

CNC (Computer Numerical Control) machining involves using automated tools and machinery controlled by computer programs to cut, shape, or fabricate parts. This subtractive technique allows for high precision and scalability. CNC machining can produce prototypes in a range of materials, including metals, plastics, and composites.

3.3 Injection Molding

While injection molding is traditionally associated with mass production, it can also be a rapid prototyping tool when used to create small runs of products for testing and validation. This process entails injecting molten material into a mold, allowing companies to produce components that closely resemble the final product in form and function.

3.4 Vacuum Casting

Vacuum casting is a process that allows for the rapid production of silicone molds for casting various materials, including polyurethane resins. It is suitable for producing a limited number of copies of a prototype that closely mimic the final product, providing excellent detail and surface finish.

Types of Rapid Prototyping

Various types of rapid prototyping technologies are available, each suited for different applications. Here’s an overview of several key types:

4.1 Functional Prototyping

Functional prototypes are intended to function like the final product, allowing for performance testing and usability evaluation. They serve as practical models to identify any flaws or required enhancements.

4.2 Visual Prototyping

Visual prototypes focus on aesthetics and design. These prototypes help stakeholders visualize the design’s appearance without necessarily functioning as a product. They are often crucial during initial feedback stages.

4.3 User Experience Prototyping

User experience (UX) prototypes prioritize a product’s usability and interface. These prototypes aim to gauge user interaction and gather feedback regarding the design’s ergonomics and accessibility.

4.4 Proof of Concept Prototypes

Proof-of-concept prototypes demonstrate the feasibility of a concept. They may not resemble the final product closely but are valuable for testing technical aspects and viability.

Advantages of Rapid Prototyping

Rapid prototyping offers a host of advantages that make it a crucial part of contemporary product development. Let’s explore some of these key benefits in depth.

5.1 Faster Iterations

The primary advantage of rapid prototyping is its ability to facilitate faster iterations. The process encourages constant testing, allowing designers and engineers to identify issues quickly and make necessary adjustments.

5.2 Flexibility in Design Changes

As ideas evolve, rapid prototyping accommodates design changes without significant disruption to the development timeline. Designers have the freedom to adapt their concepts based on user feedback and market insights, enabling responsive product development.

5.3 Low-Risk Validation

Testing prototypes in the early design stages minimizes the financial risk associated with product development. Companies can gather concrete data on how their design performs without committing to large-scale production prior to validating their ideas.

5.4 Access to a Global Market

The reduced cost and time associated with rapid prototyping empower companies to access a broader range of markets. Manufacturers can produce diverse products in varying locales tailored to specific consumer needs, ultimately enhancing global reach.

5.5 Shortened Design Cycles

Companies that utilize rapid prototyping can shorten their design cycles, allowing them to stay competitive in saturated markets. By launching products faster, businesses can optimize their chances of success and drive profitability.

Challenges of Rapid Prototyping and Solutions

Despite its numerous advantages, rapid prototyping is not without challenges. However, understanding and addressing these challenges can enhance its effectiveness.

6.1 Material Limitations

Certain rapid prototyping methods may be limited by the materials available. It is crucial to choose materials that align with intended product use, performance specifications, and environmental factors. Selecting the right method for the material type is essential.

Solution: Conduct thorough research and simulations to understand the best materials for prototypes. Collaborate with suppliers to access a wider array of material options.

6.2 Maintaining Accuracy

As prototypes undergo revisions, maintaining dimensional accuracy can become a concern. Deviations can lead to flaws in design and function, affecting the validation process.

Solution: Utilize high-precision techniques such as CNC machining and incorporate regular quality checks throughout the prototyping phases.

6.3 Balancing Speed with Quality

Striking the right balance between speed and product quality may prove challenging as teams rush to meet timelines. Rapid iterations can sometimes yield rushed designs that lack refinement.

Solution: Implement a structured review process integrated into the prototyping workflow. This practice ensures that design changes are validated at every stage of the development cycle.

Applications of Rapid Prototyping

Rapid prototyping serves various industries, supporting the development of innovative products. Here are some notable applications across different sectors:

7.1 Automotive Industry

In the automotive sector, rapid prototyping is often employed for creating mock-ups of vehicle components. This technology allows engineers to validate design and functionality while speeding up the production of vehicle parts.

7.2 Aerospace and Defense

Aerospace applications utilize rapid prototyping for creating lightweight components and complex geometries essential for aircraft performance. Rapid prototyping minimizes lead times for critical parts, allowing for swift adaptation to design changes.

7.3 Medical Devices

Rapid prototyping is vital in medical device development. Engineers use rapid techniques to create prototypes for surgical instruments, implants, and diagnostic tools that must satisfy stringent regulatory requirements.

7.4 Consumer Electronics

In the fast-paced world of consumer electronics, rapid prototyping aids in the development of prototypes for gadgets and devices, enabling designers to test aesthetics and features before launching products in highly competitive markets.

Tools and Technologies in Rapid Prototyping

Several tools and technologies facilitate the rapid prototyping process. Here are a few common ones:

8.1 CAD Software

Computer-Aided Design (CAD) software allows designers to create and modify 3D models efficiently. Programs such as SolidWorks, AutoCAD, and Rhino provide powerful features that simplify the modeling process.

8.2 3D Printers

As a central component of rapid prototyping, 3D printers come in various types and sizes, notably FDM, SLA, and SLS, each designed to suit different prototyping needs.

8.3 CNC Machines

CNC machines provide the precision required for creating high-quality prototypes. They can work with a wide range of materials to produce detailed components.

8.4 Simulation Tools

Simulation tools grant designers the ability to visualize and analyze prototypes before manufacturing. This capability reduces errors and allows teams to optimize designs early in the development process.

Case Studies: Success Stories of Rapid Prototyping

9.1 Case Study: A Leading Automotive Manufacturer

A well-known automotive manufacturer integrated rapid prototyping into its vehicle development process. By rapidly producing functional prototypes of components and subsystems, the company was able to significantly reduce its average development time from 24 months to just 15 months.

9.2 Case Study: Medical Device Innovation

A medical device startup turned to rapid prototyping for its innovative new product: a portable, non-invasive diagnostic tool. Using 3D printing, the company developed several prototypes in just weeks. Testing yielded invaluable feedback, leading to a redesign that significantly improved usability and effectiveness.

The Future of Rapid Prototyping

As new technologies emerge, the landscape of rapid prototyping continues to evolve. Advances in materials science, automation, and artificial intelligence are paving the way for even more effective rapid prototyping solutions.

**

In summary, rapid prototyping has revolutionized product development by offering unprecedented opportunities for faster iterations, cost efficiency, and improved product quality. From 3D printing and CNC machining to injection molding and beyond, the variety of processes available allows companies to tailor their prototyping strategies to suit their specific needs.

As we look to the future, the significance of rapid prototyping will continue to grow. Manufacturers will need to adapt to ever-changing market demands while delivering high-quality products in shorter timeframes. Thus, investing in rapid prototyping not only streamlines product development cycles but creates avenues for innovation and collaboration.

Whether you are looking to enhance your existing product lines or explore new market opportunities, understanding rapid prototyping is crucial in today’s fast-moving landscape. Embrace the power of rapid prototyping, and see how it can transform your product development efforts for the better.