Did you know that the global CNC machining market is expected to grow at a staggering compound annual growth rate (CAGR) of 5.89% from 2021 to 2028? This robust growth reflects the increasing demand for precision manufacturing across various industries, including aerospace, automotive, and medical sectors. One of the most significant innovations in this field is the ability of CNC (Computer Numerical Control) machining to effectively handle high-hardness materials. In this blog, we will explore the primary advantages of CNC machining when it comes to processing these tough materials, and provide detailed solutions for the challenges this entails.

The evolution of CNC machining has redefined the manufacturing landscape, particularly in the realm of high-hardness materials. These materials, known for their exceptional durability and resistance to wear, are essential in industries ranging from aerospace to mining. However, machining them presents unique challenges that require advanced techniques and precision equipment. This blog will delve deep into the advantages of CNC machining in managing high-hardness materials and provide practical solutions to maximize efficiency and quality.

2.1 What Are High-Hardness Materials?

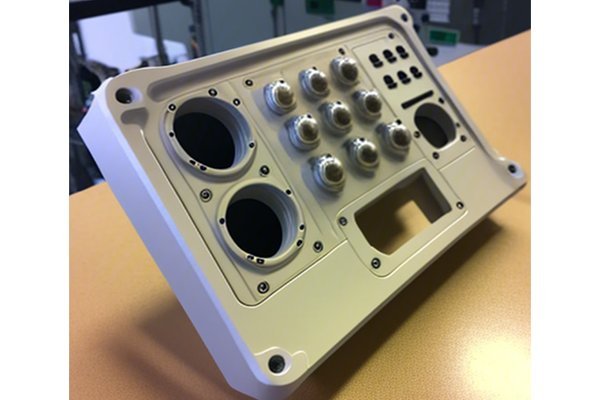

High-hardness materials include metals such as hardened steels, titanium alloys, tungsten carbide, and ceramics. These materials are characterized by their ability to withstand extreme conditions, high mechanical stress, and significant wear and tear. As a result, they are often utilized in applications where longevity and reliability are paramount.

2.2 Applications of High-Hardness Materials

3.1 What is CNC Machining?

CNC machining refers to the use of computers to control machine tools in the manufacturing process. Instead of manual intervention, CNC machines are programmed to perform precise movements to cut, mill, drill, or shape materials with high accuracy.

3.2 CNC Machining Process

The process involves several stages:

4.1 Enhanced Precision and Accuracy

One of the most significant advantages of CNC machining is its ability to maintain tight tolerances with repeatable precision. This feature is particularly crucial when working with high-hardness materials, where minor deviations can lead to catastrophic failures in applications. CNC machines can produce parts with tolerances as tight as ±0.001 inches, ensuring that components fit seamlessly in their intended assemblies.

4.2 Increased Productivity and Efficiency

CNC machining allows for high-speed manufacturing which drastically reduces lead times. Automation facilitates continuous production, and multi-tasking capability means that multiple operations can be performed without manual setup changes. For high-hardness materials that often require lengthy machining times, this efficiency is invaluable.

4.3 Reduced Waste and Cost Efficiency

By using precise tooling and advanced programming, CNC machining minimizes material waste. Accurate material removal contributes to lower production costs, helping manufacturers remain competitive in industries where high-hardness materials can be expensive.

4.4 Versatility and Flexibility

CNC machines can accommodate a range of materials and maintain performance integrity. As a result, they can adapt to process various high-hardness materials using different techniques—this versatility supports manufacturers looking to diversify their offerings without substantial investment in unique setups.

4.5 Predictable Outcomes and Quality Control

CNC machining allows for consistent quality that adheres to industry standards. Advanced inspection techniques, including in-process monitoring and digital measuring tools, enable manufacturers to maintain high quality at every stage of production.

5.1 Tool Wear and Tear

Machining high-hardness materials can lead to rapid tool wear, affecting performance and increasing costs. manufacturers must frequently replace or sharpen tools, which can disrupt production.

5.2 Heat Generation and Management

The machining of hard materials often generates significant heat, leading to thermal expansion, tool degradation, and potential compromises in the integrity of the workpiece.

5.3 Material Instabilities

Certain high-hardness materials exhibit tendencies toward distortion when machined, leading to inaccuracies. Special care must be taken to ensure that dimensional tolerances are maintained.

6.1 Choosing the Right Tools

Selecting the appropriate cutting tools is essential. Carbide tooling, coated tools, and high-speed steel are commonly employed for machining high-hardness materials. The right tool life is achieved by evaluating factors like material type, cutting speeds, and depth of cut.

6.2 Optimal Cutting Parameters

Establishing optimal cutting speeds, feeds, and depth of cuts is crucial to balancing tool life and machining efficiency.

6.3 Advanced Cooling Techniques

Utilizing cooling fluids and advanced cooling techniques, such as through-tool coolant and mist cooling, can help mitigate heat generation and prolong tool life.

6.4 Material Selection

Utilizing materials that are specifically designed for machining, such as heat-treated alloys and composites engineered for durability, can enhance quality and performance.

(Here, you’d include detailed case studies demonstrating successful applications—such as turbine blades, gear components, and surgical tools made from high-hardness materials.)

As industries continue to evolve, the demand for CNC machining of high-hardness materials will only grow. Emerging technologies, including artificial intelligence and machine learning, are expected to revolutionize CNC programming, improving efficiency, predictive maintenance, and real-time quality control.

In conclusion, CNC machining holds immense potential for effectively producing high-hardness materials. Through its unparalleled precision, productivity, versatility, and quality control, it stands as a critical technology across varied industries. However, challenges associated with tool wear, heat management, and material stability cannot be overlooked. By implementing the right solutions, manufacturers can optimize their CNC machining processes and maintain a competitive edge. This blog highlights not only the advantages of CNC machining for high-hardness materials but also its importance within the manufacturing landscape. As technology evolves, staying informed about these advancements will be key to thriving in an increasingly complex and demanding marketplace.

Ultimately, investing time to understand CNC machining’s value in high-hardness materials is essential for any manufacturer aspiring for excellence in quality and performance. So as you consider your production strategies, remember that mastering CNC machining can lead to substantial benefits and a sustainable future in manufacturing.