Did you know that the choice of material in CNC machining can significantly cut down production time by as much as 30% to 50%? As technology continues to evolve, engineers, manufacturers, and product designers constantly face a critical decision: which materials to use for optimal results. With the ever-increasing demand for efficiency and precision, knowing how different materials perform under CNC machining is crucial. Today, we’ll dive into an exploration of the processing time differences between 5052 aluminum and transparent polycarbonate (PC) plastic, shedding light on their specific characteristics, machining efficiencies, and what that means for industry applications.

Understanding CNC Machining

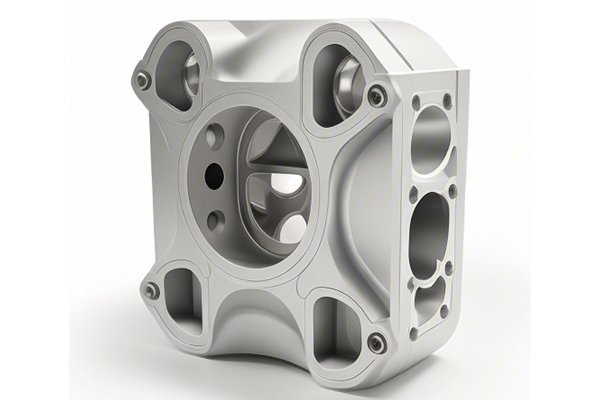

Before we delve deeper, let’s refresh our understanding of CNC (Computer Numerical Control) machining. CNC machining is an advanced manufacturing process that employs computerized controls to operate machines, tools, and equipment. It’s utilized in various applications, including metalworking and plastic fabrication. The process involves removing material from a solid block (or workpiece), achieving precise dimensions and surface finishes through methods such as milling, turning, and drilling.

Material Profile: 5052 Aluminum vs. Transparent PC Plastic

To make informed decisions about machining materials, understanding their properties and behavior during machining is essential. Here, we will focus on two popular materials: 5052 aluminum and transparent polycarbonate (PC) plastic.

5052 aluminum is an alloy primarily made of aluminum, magnesium, and manganese with added elements that enhance its mechanical properties and corrosion resistance. Here are its key characteristics:

Transparent PC plastic is a high-performance thermoplastic known for its outstanding clarity and toughness. Here are the significant attributes:

Processing Time Considerations

With a solid understanding of each material’s properties, the next step entails examining their processing times during CNC machining. Various factors can impact the machining efficiency of both materials:

The setup time for machining operations can vary based on the complexity of the part. Setting up tools for machining aluminum may be more time-consuming compared to PC, which can lead to additional overhead.

Material removal rates can be a vital determinant of machining efficiency.

Both materials necessitate attention to precision requirements and potential post-processing needs, affecting total processing times.

Comparative Analysis of CNC Machining Time

To illustrate the points discussed, let’s consider a typical scenario involving the CNC machining of a simple part—say, a bracket designed to support lightweight equipment.

Scenario 1: Machining a 5052 Aluminum Bracket

Scenario 2: Machining a Transparent PC Bracket

Given these examples, the transparent PC bracket clearly demonstrates a shorter total machining time (2.5 hours) compared to the aluminum bracket (5 hours). This difference may vary based on part complexity and size but typically highlights a trend observed across numerous applications.

Choosing the Right Material: Practical Considerations

While processing times are important, the ultimate decision on material selection should be based on various performance factors. Here are some practical considerations:

Consideration of application requirements is paramount—certain applications necessitate the strengths or properties of one material over another. You must evaluate if strength, weight, clarity, or aesthetics are critical for your final design.

Cost implications often play a significant role in material selection. While aluminum may be costlier in machining due to tool wear and slower processing times, its longevity and durability can provide long-term savings.

For high-volume production, consider whether the material will allow for scalable production. Transparent PC may allow quicker turnaround times for prototypes, while aluminum might be more suitable for structures requiring robust characteristics.

Navigating the world of CNC machining entails understanding how material properties affect processing times, thereby influencing manufacturing efficiency. This blog has examined the processing time disparities between 5052 aluminum and transparent PC plastic, highlighting their respective properties, machining efficiencies, and best application scenarios.

Through our exploration, we uncovered that while 5052 aluminum provides superior strength and rigidity, transparent PC plastic offers flexibility and quicker machining times, making both materials valuable in specific contexts. The decision ultimately rests on an integration of application requirements, budgetary constraints, and production goals.

Remember, the choice of material could significantly impact production timelines and costs—allowing design engineers and manufacturers to optimize their workflows effectively. As technology continues to advance, understanding the nuances of material processing will become increasingly critical in achieving a competitive advantage in the marketplace.

In a world where time efficiency and product reliability dictate market success, investing time to carefully consider which material to utilize in CNC machining isn’t just wise; it’s essential.