: The Impact of Vibration on CNC Machining

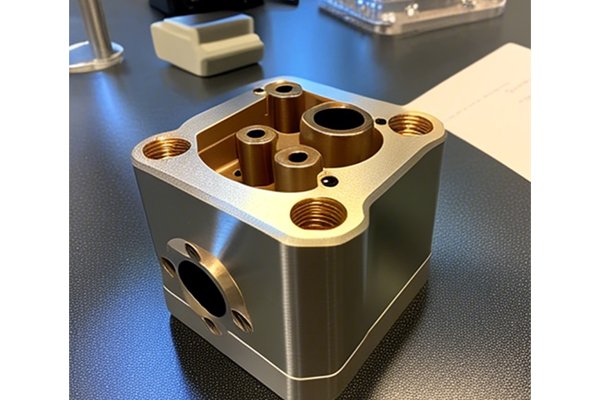

Did you know that excessive vibration in CNC machining can lead to a 30% decrease in tool life? As manufacturers strive for precision and quality production, vibrations during the machining process can significantly impede these goals. Particularly when working with aluminum alloys, which are popular for their lightweight and high-strength properties, understanding how to control vibration is crucial for maintaining both the quality of the finished product and the longevity of the machinery involved.

In this blog, we will explore the challenges that vibration presents in CNC machining of aluminum alloys and provide detailed techniques and solutions to minimize it. By the end of this comprehensive guide, you will be equipped with valuable insights that can enhance your CNC machining processes, leading to improved productivity and cost-efficiency.

—

Understanding Vibration in CNC Machining

Before diving into solutions, it is essential to comprehend the sources and types of vibration that can affect CNC machining. Vibration can originate from several types of disturbances, including:

Types of Vibration

Solutions to Reduce Vibration in Aluminum CNC Machining

Now that we’ve established what vibration is and its sources, let’s delve into practical solutions to mitigate this challenging issue:

One of the first lines of defense against vibration is to optimize your cutting parameters:

Choosing the right tools and optimizing their design can have a profound effect on vibration levels:

Modern CNC machines often come equipped with vibration control technologies:

A securely mounted workpiece reduces the chances of vibration during machining:

Regular inspection and maintenance can significantly lessen vibrations caused by equipment wear and tear:

Advanced Techniques to Consider

FEA is a computational tool used to predict how machines will react to forces, vibrations, and other environmental factors. Utilizing FEA can allow engineers to make informed decisions on design adjustments to minimize vibrations.

When machining softer aluminum alloys, threaded inserts can assist in firmly securing the workpiece, thereby reducing vibrations.

Utilizing advanced CAM software to create optimized tool paths can help minimize vibration through better distance management and smoother transitions.

The Importance of Employee Training

No solution can be effective without proper training. Ensure that your employees are knowledgeable about:

—

: The Value of Minimizing Vibration in CNC Machining

In conclusion, managing vibration in CNC machining of aluminum alloys is not only crucial for extending tool life and ensuring quality output but also for promoting overall efficiency in manufacturing processes. Through optimization of cutting parameters, investment in advanced technology, and rigorous maintenance and training, businesses can see significant returns on investment.

The techniques and solutions discussed in this blog are essential for anyone involved in the CNC machining of aluminum alloys. As the industry continues to evolve, embracing these strategies will aid organizations in staying competitive and delivering high-quality products.

As you move forward, remember that reducing vibrations is not just about immediate results; it’s about cultivating a long-term culture of quality and efficiency. Your commitment to minimizing CNC machining vibrations will not only enhance production quality but also strengthen your position in an increasingly competitive marketplace.

Thank you for investing your time in understanding the importance of minimizing vibration—this knowledge could very well transform your machining processes.