Did you know that the global digital camera market was valued at approximately $11.8 billion in 2020 and is projected to decline to about $8.4 billion by 2025? This drastic decline reflects not just changing consumer preferences but also the rapid evolution in technology. One of the unsung heroes of this industry are the precise and complex components manufactured through CNC turning, which are crucial to maintaining the performance and reliability of camera systems. This blog post aims to delve into the intricate world of CNC turning, particularly focusing on its technical requirements for producing camera parts.

The Allure of CNC Turning in Camera Manufacturing

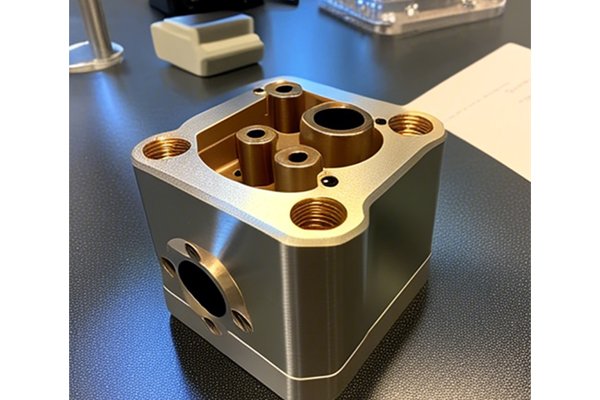

CNC, or Computer Numerical Control, is a manufacturing process that utilizes pre-programmed computer software to control the movement of factory tools and machinery. The level of precision that CNC turning brings to the table makes it an indispensable option for fabricating components that demand high tolerances, such as those used in camera lenses, frames, and other critical internal parts.

As you might imagine, the arena of camera components is not just about aesthetics; it’s about functionality, performance, and reliability. As such, the requirements for CNC turning in this context can be quite stringent.

Key Technical Requirements for CNC Turning of Camera Parts

The CNC Turning Process: Step-by-Step

Step 1: Design and Prototyping

The first critical phase in the CNC turning of camera parts involves a precise design that takes into account all technical requirements. This step usually employs CAD (Computer-Aided Design) software to create detailed 3D models, which serve as the blueprint for machining. Rapid prototyping can also be used to produce initial models and identify potential design flaws before large-scale production.

Step 2: Material Preparation

Once the design phase is complete, the next step is selecting the appropriate material. After materials are procured, they must be cut into manageable sizes for the CNC lathe, following loading and setup procedures.

Step 3: Tool Setup

Setting up the tools according to specifications is critical. This includes choosing the right cutting tools, tool holders, and turning inserts, which must be carefully aligned for optimal machining.

Step 4: Programming

G-code is generated from the CAD model, either manually or through CAM (Computer-Aided Manufacturing) software. This dictates all movements and operations of the CNC machine during the turning process.

Step 5: Machining

The actual process of CNC turning involves feeding the material into the machine and precisely controlling the cutting tool movements according to the programmed code. The CNC machine can perform a variety of operations, including facing, tapering, and grooving, to achieve the desired part geometry.

Step 6: Quality Control

Post-machining, every part must undergo rigorous inspections. Measurements are taken using precision tools to confirm that they meet technical requirements. If deviations are found, recalibration of the CNC machine or adjustments in tool selection might be necessary.

Step 7: Finishing

Surface finishes may be enhanced through additional processes such as polishing, anodizing, or painting, which not only improve aesthetics but also promote corrosion resistance or friction reduction.

Step 8: Assembly and Testing

Finally, CNC turned parts are often assembled with other components to create the final product. Rigorous testing simulates real-world conditions to ensure that every part functions smoothly and meets both safety and performance standards.

The Importance of Adhering to Technical Requirements

Understanding and implementing the technical requirements for CNC turning of camera parts is fundamental for various reasons.

: A Pillar of Precision in Camera Manufacturing

In this intricate dance of modern manufacturing, CNC turning stands out as a critical component in producing high-precision camera parts. From stringent material selection to meticulous programming and quality control, each aspect plays a pivotal role in the final outcome. This blog serves as a comprehensive guide for manufacturers seeking to understand the technical requirements essential for CNC turning, especially within the camera industry.

Reflecting on the advancement of technologies and shifting consumer trends offers insights into the future of CNC machining. The continuous evolution of CNC technology promises better tools, smarter machines, and enhanced capabilities to tackle complex demands.

Ultimately, the importance of adhering to these technical requirements cannot be overstated. As the camera industry continues to innovate, the manufacturers that prioritize precision and quality will not only survive but thrive in this dynamic landscape. Whether you’re a seasoned professional or a newcomer to the field, understanding these guidelines is vital for achieving optimal results in CNC turning and maintaining your competitive edge. Explore these techniques further and consider how they may apply to your workflow for sustained success in this fast-paced industry.