Did you know that the global CNC machining market is expected to reach $100 billion by 2025? This remarkable growth is fueled by the increasing demand for precision parts across a variety of industries, from healthcare to automotive. As industries evolve and their requirements become more complex, the need for customized services in plastic CNC machining has never been more critical. But how exactly can customized services meet these diverse needs?

In this extensive blog post, we will explore the multifaceted applications of plastic CNC machining, how customization plays a crucial role, and the challenges that businesses face in this dynamic environment. Additionally, we’ll delve into potential solutions, best practices, and innovative approaches that can help companies leverage CNC machining to its fullest potential.

The Rise of CNC Machining: Understanding the Basics

Before we dive deep into customized services, let’s understand what CNC machining entails. CNC stands for Computer Numerical Control, a manufacturing process that utilizes pre-programmed computer software to control machine tools. This technology is prevalent in the production of plastic parts and offers several advantages over traditional machining methods, including increased precision, efficiency, and versatility.

Different Types of Plastic Suitable for CNC Machining

A variety of plastics can be used in CNC machining, each chosen based on the application’s requirements:

By understanding the unique properties of each type of plastic, businesses can better match materials to their specific needs.

The Importance of Customization in Plastic CNC Machining

As industries become more specialized, the one-size-fits-all approach no longer suffices. Customization in plastic CNC machining allows businesses to tailor parts to their exact specifications, which significantly enhances product performance and efficiency. Below, we outline how customization can effectively accommodate diverse industry needs.

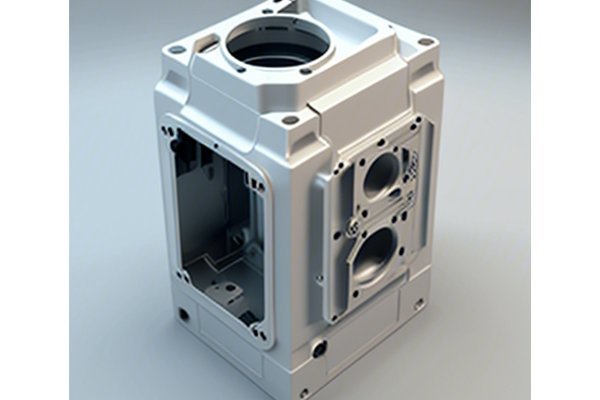

One of the primary advantages of customization in CNC machining is the ability to create tailored designs that meet unique specifications. Whether for intricate components in medical devices or specialized parts in automotive manufacturing, CNC machining can create precise geometries that off-the-shelf products simply cannot match.

Solution: Engage in a collaborative design process where engineers and machinists evaluate initial designs. Prototyping using CNC machining can bridge the gap between concept and final product.

Every industry has specific requirements when it comes to materials. Medical applications may require biocompatible plastics, while aerospace applications might need lightweight but durable composites. Customized CNC machining allows for the selection of materials that meet unique performance criteria, such as tensile strength, heat resistance, and chemical stability.

Solution: Develop a materials library or database that outlines the properties of various plastics. This can serve as a useful tool in the custom fabrication process, ensuring the right material is chosen for each application.

In industries such as electronics and aerospace, tolerances can be extraordinarily tight. CNC machining allows for incredible levels of precision, making it possible to produce parts that meet these stringent requirements. Customization enables companies to specify exactly the tolerances they need and integrate sophisticated calibration systems to ensure quality.

Solution: Utilize advanced CAD/CAM software for modeling and simulating machining processes. This enables engineers to assess potential issues related to tolerances before production.

Businesses often experience fluctuating demand based on seasonal or market changes. CNC machining offers flexibility in production volume, allowing companies to scale their manufacturing efforts according to need. Customization of CNC setups can facilitate short runs of specialized parts without needing major redesigns.

Solution: Invest in flexible CNC systems that allow for quick changes to tooling and programs. This adaptiveness will enable quicker response times to changing market demands.

With the rise of rapid prototyping and on-demand production, businesses can significantly reduce lead times by customizing CNC machined parts to their specific requirements. Custom services streamline the manufacturing process and eliminate bottlenecks.

Solution: Streamline your workflow by integrating Just-In-Time (JIT) practices. This emphasizes efficient inventory management and shortens production times.

For industries where appearance matters—such as consumer goods and automotive interior design—CNC machining allows for the integration of various surface finishes and aesthetics. Companies can customize their orders to achieve the look and feel they desire.

Solution: Offer different finishing techniques such as bead blasting, anodizing, or painting. Including restoration or improvement options for traditional finishes will also appeal to clients seeking premium products.

Challenges in Customized CNC Plastic Machining

While customization provides a wealth of advantages, it also poses several challenges that companies must navigate.

Customized services may require higher initial investments for specialized tools or programming needs. For businesses operating on tight budgets, this can be a significant barrier.

Solution: Create a comprehensive cost-benefit analysis to demonstrate the long-term savings and efficiencies customized services can provide.

The intricate designs often required for customized parts can complicate the machining process. This complexity can lead to longer production times and a greater chance of error.

Solution: Implement thorough quality control measures at each step of the manufacturing process to catch issues before they become larger problems.

With unique requirements, sourcing the right materials and components can become more complicated. Delays in the supply chain can impact production schedules.

Solution: Establish relationships with multiple suppliers and develop strong logistics strategies. This diversification will prepare businesses for supply chain disruptions.

Industry-Specific Applications of Customized CNC Machining

The medical industry demands precision, compliance with regulatory standards, and reliability. Plastic CNC machining can create components from surgical instruments to prosthetics that meet these rigorous needs.

In aerospace, safety and durability are paramount. Custom machining allows for lightweight yet strong components that meet strict industry tests.

The automotive sector utilizes customized CNC machining extensively—from manufacturing complex fuel management systems to interior features, ensuring both performance and aesthetics.

With the continuous push for miniaturization in electronics, CNC machining can produce compact and tight-tolerance components crucial for performance.

Customized plastic CNC machined parts can enhance product appeal while fulfilling specific functional requirements, from ergonomic features to stylish designs.

Best Practices for Successful Customization

To maximize the benefits of customized services in plastic CNC machining, businesses should consider the following best practices:

The Future of Customized Plastic CNC Machining

As technology advances, the possibilities for customized plastic CNC machining will expand even more. Innovations such as Artificial Intelligence (AI) and Machine Learning are poised to revolutionize the field, offering predictive analytics for improved efficiency and decision-making.

In conclusion, customized services in plastic CNC machining are not just an enhancement; they are becoming a necessity across wide-ranging industries. By understanding the unique needs of your sector and embracing customization, companies can reap the benefits of precision, efficiency, and adaptability.

This blog has explored how tailored solutions can address specific industry demands and navigate potential challenges. As businesses consider their CNC machining needs, recognizing the importance of customization will ultimately lead to enhanced quality, satisfaction, and competitive advantage.

In navigating this complex landscape of CNC machining, constant evaluation and innovation are key. Don’t just adapt to the industry’s changes; lead the way. Understanding the intricacies of customized services will better prepare your business for future challenges and opportunities in the ever-evolving world of CNC machining. Think about implementing these strategies now, and position your brand as a leader in customized CNC solutions.