Did you know that the automotive industry is projected to use nearly 25 million tons of plastic annually by 2025? This staggering number highlights the crucial role that plastics play in the production, performance, and sustainability of modern vehicles. As automakers continue to explore innovative materials to enhance performance and reduce weight, Computer Numerical Control (CNC) machining emerges as a vital process in manufacturing automotive components from various plastics. In this blog, we will explore the ways CNC machining optimizes the performance of automotive parts made from different plastics, the challenges faced in the process, and practical solutions to these challenges.

The Role of Plastics in Automotive Manufacturing

The automotive industry relies on a variety of plastics to meet the demands for durability, lightweight construction, and cost-effectiveness. With properties such as corrosion resistance, thermal stability, and design versatility, plastics such as Polypropylene (PP), Polycarbonate (PC), and Nylon have become integral in manufacturing parts ranging from dashboards to fuel tanks.

However, the choice of plastic is just one component of the performance puzzle; the manufacturing process is equally significant. CNC machining offers precision and repeatability that traditional manufacturing methods struggle to match, making it the perfect choice for producing high-quality automotive parts.

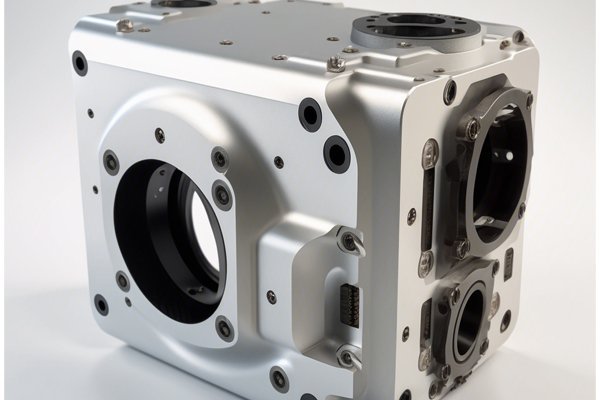

Understanding CNC Machining

CNC machining is a subtractive manufacturing process that utilizes computerized controls to manipulate tools and equipment. This automation ensures high accuracy, allowing for precisely engineered components that conform to specifications.

Advantages of CNC Machining in Automotive Manufacturing:

The Impact of Plastics on Performance

To better understand how CNC machining can enhance automotive parts, it’s essential to explore the characteristics of commonly used plastics.

Common Plastics Used in Automotive Parts:

Improving Performance Through CNC Machining

Now that we’ve established the significance of plastics and CNC machining let’s delve into how this technology enhances the performance of automotive parts made from different plastics.

CNC machining can optimize the performance of plastic automotive parts by reinforcing their strength and durability. By employing techniques such as selective reinforcement (e.g., embedding fiberglass in nylon), manufacturers can create components that withstand stress and impact.

Solution: For instance, when machining nylon for gears, utilizing CNC techniques to design reinforced areas can lead to improved load-bearing capacity and longevity.

In automotive applications where components must fit together seamlessly, the precision of CNC machining becomes indispensable.

Solution: Automakers can use CNC machining to create parts like brackets and housings to tight tolerances. Employing advanced measurement tools and techniques during the manufacturing process helps verify that the parts meet necessary specifications before assembly.

CNC machines can produce intricate shapes and designs that would be nearly impossible to achieve through traditional methods.

Solution: For example, complex interior components such as instrument panels may include multi-functional features, achieved through CNC machining. Automakers can design these components to enhance aesthetic appeal while providing additional utility, such as integrated storage.

Weight reduction is a key factor in improving fuel efficiency and performance. CNC machining allows manufacturers to create lightweight plastic parts that maintain structural integrity.

Solution: By adopting a lattice design in components, CNC machining can remove unnecessary material while ensuring that the component retains its load-bearing capabilities.

CNC machining can achieve exceptional surface finishes, essential for aesthetic components as well as for parts that fit tightly together.

Solution: Advanced CNC techniques can achieve finishes that reduce friction in moving components, improving efficiency and prolonging the lifespan of parts made from plastics like Nylon or PTFE (Teflon).

Challenges in CNC Machining of Plastic Parts

While CNC machining offers numerous benefits for manufacturing automotive components, there are also challenges that manufacturers must overcome:

Not all plastics are suitable for CNC machining due to varying properties. Understanding the specific machining characteristics of different plastics is essential.

Certain plastics can lead to more rapid tool wear due to their abrasive nature. This wear can affect machining accuracy.

Some plastics may deform under high cutting speeds or temperatures, affecting the dimensional integrity of the machined parts.

Many engineering-grade plastics absorb moisture, which can alter their physical properties over time and influence machining accuracy.

Solutions to Address Challenges

Select durable carbide or diamond-coated tools designed specifically for machining plastics. Using tools with sharper edges can help produce cleaner cuts, reducing the risk of melting or chipping.

Evaluate spindle speed, feed rate, and cooling methods to optimize for the specific type of plastic being machined. Lower speeds and adequate cooling can mitigate the risks of thermal deformation.

Pre-dry high-moisture plastics before machining to minimize moisture absorption effects. This process helps to ensure that the physical properties remain stable during machining.

Implement stringent quality control measures throughout the machining process to monitor tolerances and detect potential defects early on.

Train operators in best practices for machining different plastics, emphasizing efficient tool usage and the specific challenges associated with each material.

Sustainable Practices in CNC Machining

As the automotive industry shifts toward sustainability, CNC machining can contribute significantly through processes that promote recycling and waste reduction.

The Future of CNC Machining and Automotive Plastics

The future of CNC machining in the automotive industry appears promising. With advancements in technology such as AI-driven machining and new plastic composites, manufacturers will continue to push the boundaries of what is possible.

CNC machining plays an indispensable role in enhancing the performance of automotive parts made from different plastics. From improving dimensional accuracy to achieving complex geometries while minimizing waste, this process unlocks immense potential in automotive manufacturing.

By mastering the techniques discussed in this blog, manufacturers can not only meet the increasing demands of the automotive industry but also innovate for a sustainable and efficient future. As you consider the significance of CNC machining in the automotive sector, remember that each advancement made in this field translates to improved vehicle performance, safety, and environmental impact. Embrace the future of automotive manufacturing and continue the journey of exploration and discovery in the world of CNC machining!