: The Unseen Forces at Play

Did you know that nearly 80% of all engineering failures are attributed to material fatigue and thermal stress? This statistic underscores the critical importance of understanding the factors that affect material performance, especially in industrial applications where metals like aluminum alloys are extensively used. Aluminum alloy housings are ubiquitous in various sectors, including aerospace, automotive, electronics, and construction. However, thermal stress poses a significant challenge to their longevity and performance.

In today’s blog, we will delve deeply into the impact of thermal stress on aluminum alloy housings, explore why it occurs, and provide actionable strategies to prevent its detrimental effects. This comprehensive guide will be invaluable for engineers, designers, and anyone involved in the manufacturing process of aluminum components.

Understanding Thermal Stress

What is Thermal Stress?

Thermal stress arises from changes in temperature within a material or between different materials in contact. When a material is heated, it tends to expand, and when cooled, it contracts. If these changes are not uniform, or if they occur too rapidly, internal stresses can build up. In aluminum alloys, these stresses can compromise structural integrity and lead to various forms of failure, such as cracking or warping.

Why is Thermal Stress Concern for Aluminum Alloys?

Aluminum alloys are preferred in many applications due to their lightweight, corrosion resistance, and good mechanical properties. However, their relatively high coefficient of thermal expansion means they are susceptible to thermal stress. Factors such as rapid temperature fluctuations, differential heating, and constraints from other connecting components can exacerbate the issue, making it crucial to address.

The Effects of Thermal Stress on Aluminum Alloy Housings

One of the most immediate impacts of thermal stress is on structural integrity. When thermal stress exceeds the yield strength of the aluminum alloy, it can lead to permanent deformation or even total failure. For instance, in aerospace applications, where safety is paramount, any loss of structural integrity can have catastrophic consequences.

Thermal stress can lead to dimensional changes in aluminum housings, which can affect assembly processes and the performance of the final product. Components that should fit together tightly may experience gaps or misalignments, leading to functional failures.

Repeated thermal cycling can induce fatigue in aluminum alloy housings. This cyclic loading can result in microscopic cracks that grow over time, eventually leading to an early failure of the component. Manufacturers often rely on component longevity, making this a critical issue.

Interestingly, thermal stress can also affect the protective oxide layer of aluminum alloys. If the thermal stress leads to cracking, the protective layer may be compromised. This exposes the bare metal to environmental factors that can accelerate corrosion.

Analyzing the Causes of Thermal Stress in Aluminum Alloys

Before we can effectively prevent thermal stress, we need to understand its root causes. Here are a few key factors contributing to thermal stress in aluminum alloy housings:

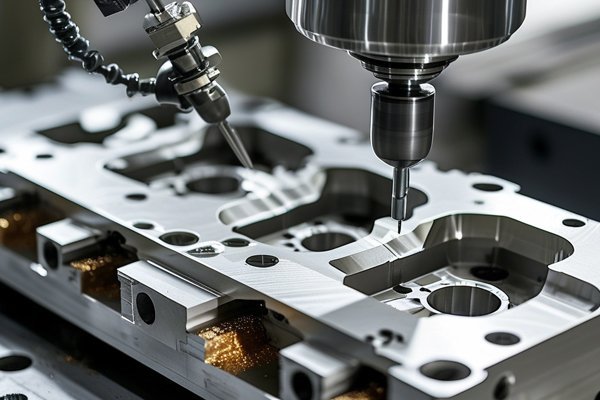

The methods used in the manufacturing of aluminum components, such as casting, welding, or machining, can introduce residual stresses. Rapid cooling processes can also lead to uneven temperature distributions, inducing thermal stress.

Temperature fluctuations due to changing environmental conditions can induce thermal stress. For example, a component exposed to direct sunlight can heat up quickly while the inside remains relatively cool, resulting in internal thermal gradients.

In many cases, aluminum alloy housings are assembled with other components. If the other components have different thermal expansion properties, this can lead to constraints that induce stress.

Finally, the operational environment can significantly affect thermal stress. For instance, components in high-temperature machinery might undergo extreme thermal cycling, further exacerbating the effects.

Solutions and Prevention Strategies for Thermal Stress

Understanding the causes of thermal stress is one part of the equation; finding effective solutions and prevention strategies is the next. Here are tried-and-true methods to mitigate the impact of thermal stress on aluminum alloy housings:

Choosing the right aluminum alloy can make a significant difference. Alloys with better thermal stability, such as 6061 or 7075, tend to perform better under thermal stress conditions. Engineers should analyze the specific requirements of the application and select materials that can withstand anticipated temperatures.

Design plays a significant role in managing thermal stress. Here are several design strategies to consider:

Annealing and Heat Treatment

After manufacturing, components can undergo annealing or other heat treatments to relieve residual stresses. This process reduces the likelihood of thermal stress generating during service.

Gradual Cooling Techniques

For processes like welding or casting, implement gradual cooling methods to minimize temperature differentials that cause stress.

Machining Techniques

When machining aluminum alloys, use techniques that reduce material removal rates to avoid excessive heat generation.

In applications where aluminum housings are subjected to extreme temperatures, consider adding thermal insulation materials. Insulating the housing can buffer against environmental heat and reduce thermal cycling effects.

Maintaining regular inspection schedules can help catch thermal-related issues before they lead to failure. Operators should look for signs of deformation, cracks, and other anomalies that indicate thermal stress has been a factor.

: Ensuring the Longevity of Aluminum Alloy Housings

In summary, thermal stress presents a formidable challenge to the performance of aluminum alloy housings, affecting structural integrity, dimensional stability, and overall lifespan. Understanding the causes—from manufacturing processes to operational conditions—allows engineers and manufacturers to adopt effective prevention strategies.

By selecting the appropriate material, implementing thoughtful design changes, employing controlled manufacturing processes, and adopting regular inspection protocols, the negative effects of thermal stress can be significantly mitigated. It’s essential for anyone involved in aluminum alloy housing production to actively consider these factors to enhance both the safety and longevity of their products.

This blog is important because it highlights a key issue affecting many industries reliant on aluminum alloy components. By being proactive and informed, we can create safer, more efficient products that stand the test of time. So, next time you think of aluminum alloy housings, remember that nuanced understanding and thoughtful design can make a significant difference in their performance and reliability.

In the ever-evolving landscape of manufacturing and engineering, let us not overlook the unseen forces at play—because stability today fosters innovation tomorrow.