By: YL Machining

—

—

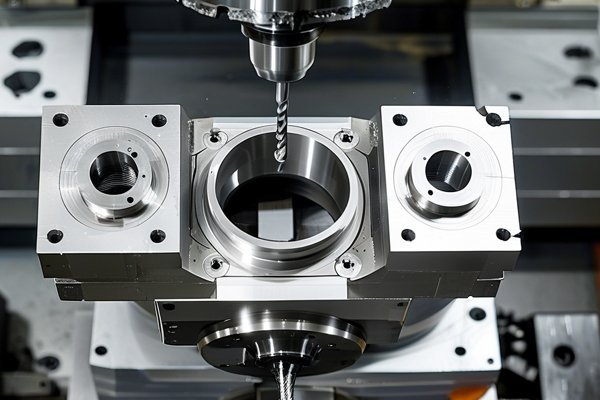

In the fast-paced world of manufacturing, precision is paramount. At YL Machining, we understand that achieving an impeccable dimensional accuracy in CNC processing, especially for aluminum alloy shells, can make or break the success of a project. This article serves as a thorough exploration of this critical aspect, aimed at equipping engineers, manufacturers, and enthusiasts with the knowledge and strategies necessary to ensure flawless outcomes.

Understanding CNC Processing

Computer Numerical Control (CNC) machining represents the backbone of modern manufacturing. This sophisticated technology utilizes computer software to control machine tools, enabling the production of complex geometries with high precision, repeatability, and efficiency. CNC machining is particularly favored for aluminum alloys due to their lightweight and malleability, making them ideal for various applications ranging from aerospace to automotive industries.

As CNC machining continues to evolve, the demand for dimensi onal accuracy has surged. This necessity arises from the growing complexity of designs and the requirement for interoperability among components. Therefore, ensuring that each piece meets its specified dimensions is essential for assembly and functionality.

Importance of Dimensional Accuracy

Dimensional accuracy in CNC processing encompasses the following facets:

Factors Affecting Dimensional Accuracy in CNC Machining

Understanding the various factors that influence dimensional accuracy is crucial for continual improvement. These factors can typically be classified into the following categories:

4.1 Material Properties

Different materials exhibit unique characteristics that can impact machining processes. Aluminum alloys, for instance, may have varied thermal expansion rates or different hardness levels, affecting their machinability. Moreover, variability in the material’s microstructure can lead to inconsistencies in performance. Therefore, it’s critical to choose the right aluminum alloy for your application and understand its properties fully.

4.2 Machine Calibration

The CNC machine must be precisely calibrated to ensure dimensional accuracy. Poorly calibrated machines can lead to cumulative errors in part dimensions. Calibration involves regularly checking the machine’s components—such as the spindle, axes, and tooling—to ensure they operate within desired tolerances. It’s highly advised to create a calibration schedule propped by standard operating procedures.

4.3 Tool Selection

The tools used in CNC machining directly impact dimensional accuracy. Selecting the appropriate tool material, geometry, and coating can significantly influence cut quality. For example, using high-speed steel (HSS) tools for tougher materials or carbide tools for high wear resistance can lead to improved precision.

4.4 Environmental Conditions

Temperature and humidity fluctuations can also affect machining accuracy. Extreme temperature changes may lead to material expansion or contraction, causing dimensional variations. Proper environmental controls in the machining area—such as temperature regulation—can mitigate these effects.

Best Practices for Ensuring Dimensional Accuracy

Tackling the challenges of dimensional accuracy can be achieved through a combination of innovative practices and rigorous attention to detail:

5.1 Design Optimization

Optimizing component design for manufacturability not only enhances accuracy but also reduces processing time and costs. Employing design software that simulates machining processes can help identify potential issues before production begins. Utilizing techniques like Design for Manufacturability (DfM) ensures that the parts produced are not just theoretically sound, but are also practical to machine.

5.2 Quality Control Measures

Quality control is integral to maintaining dimensional accuracy. Implementing a statistical process control (SPC) system helps monitor the machining process in real-time. This system collects data that can be analyzed to identify trends and variances. Regular inspections using coordinate measuring machines (CMM) allow for precise dimensional verification against design specifications.

5.3 Advanced Technologies Integration

Incorporating advanced technologies—such as 3D printing, machine learning, and sensor technologies—into the CNC process has shown to enhance dimensional accuracy. For instance, sensors that provide feedback about cutting conditions can be utilized for adaptive machining, adjusting parameters on the fly to maintain precise measurements.

Case Studies: Successful Dimensional Accuracy Achievements

At YL Machining, we have harnessed the aforementioned methods to achieve remarkable dimensional accuracy in several projects:

Achieving dimensional accuracy in CNC processing of aluminum alloy shells is not a mere goal; it is a commitment that requires an intricate understanding of both the process and the materials involved. By prioritizing factors such as material properties, machine calibration, careful tool selection, and environmental considerations, integrated with rigorous quality control measures and advanced technological implementations, manufacturers can unlock new levels of precision.

At YL Machining, we are passionate about precision. Our dedication to dimensional accuracy not only enhances functional performance but solidifies our reputation as leaders in the industry. We invite you to join us on this journey to excellence, as we redefine the possibilities of CNC machining.

FAQs

References

—