In the marvelous world of coffee machines, every component plays a vital role in delivering the delightful experience we crave. If you’re involved in designing or manufacturing coffee machine accessories, understanding the nuances of CNC (Computer Numerical Control) machining can elevate your products to an astonishing level. At YL Machining, we believe in the power of precision and quality, and we’re here to guide you through the labyrinth of material selection and machining processes that ensure excellence.

: The Essence of CNC Machining

CNC machining is a revolutionary technology that employs computer-controlled tools to fabricate parts with incredible precision. This process can efficiently transform raw materials into complex shapes and forms that are crucial for high-quality coffee machines. However, how do you ensure that the right materials are selected and the most efficient machining processes are employed?

This article serves as a comprehensive guide to help you navigate this pivotal decision-making process. We’ll delve into material properties, the intricacies of machining processes, and key considerations to optimize performance and durability in coffee machine accessories.

Why Choose the Right Materials?

The selection of raw materials is foundational and influences nearly every aspect of your coffee machine accessory—performance, durability, aesthetics, and cost. Just as a fine coffee blend requires quality beans, your products demand quality materials. Let’s explore the most common materials used in CNC machining for coffee machine accessories:

Material Properties That Matter

Choosing the right material goes beyond simply picking one from a list. It requires an understanding of the properties that affect performance:

Analyzing Machining Processes

Once you’ve identified the materials you wish to use, the next critical step involves selecting the appropriate CNC machining processes. Here are some of the most critical methods:

Evaluating Processes for Coffee Machine Accessories

Selecting a machining process involves evaluating your design requirements against capabilities. Here’s a guideline:

Cost-Effectiveness in Choosing Materials and Processes

Budget plays a significant role. While premium materials and high-tech processes are indeed beneficial, balance is key:

Practical Case Studies: YL Machining Success Stories

At YL Machining, we’ve seen first-hand how the right choices can lead to impressive outcomes. Here are practical applications where optimal material and process selections made a significant difference:

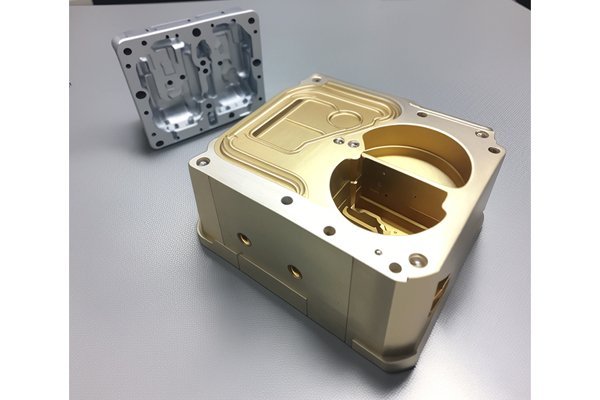

Case Study 1: Custom Aluminum Housings

A client sought to produce lightweight housing for their coffee machine. By selecting a combination of 6061 aluminum and CNC milling techniques, we achieved a robust design while ensuring efficient production and reduced weight. The result? A sleek, modern housing that maintained structural integrity under heat and pressure.

Case Study 2: Stainless Steel Components

For another project, a client wanted durable internal components for commercial espresso machines. We suggested 304 stainless steel due to its exceptional corrosion resistance and strength. The machined parts performed exceptionally well, leading to a longer life cycle and happier customers.

Tips for Successful CNC Machining

Finally, keeping a few key tips in mind can drastically improve your CNC machining outcomes:

: sculpting the future of coffee machine accessories

Choosing the right materials and machining processes requires careful consideration and expertise. By understanding material properties and machining capabilities, you can achieve accessories that not only meet but exceed your customers’ expectations.

At YL Machining, we’re passionate about precision and committed to delivering unmatched quality in every project. We hope this guide empowers you as you embark on your journey to create exceptional coffee machine accessories. Engage us for more tailored advice, and let’s brew excellence together!

Now, as you prepare to embark on your next project, remember: the right choices lead to extraordinary results, and in the world of coffee machines, every detail counts!