In the ever-evolving world of manufacturing, CNC (Computer Numerical Control) machining stands as a pillar of precision and efficiency, particularly in the burgeoning industry of electronic cigarette production. At YL Machining, we strive to remain at the forefront of this dynamic field, constantly seeking innovative ways to optimize cost control and production efficiency. This comprehensive guide explores the intricacies of CNC machining for electronic cigarette shells while providing actionable insights aimed at enhancing operational practices, reducing waste, and maximizing profitability.

Understanding the CNC Machining Process

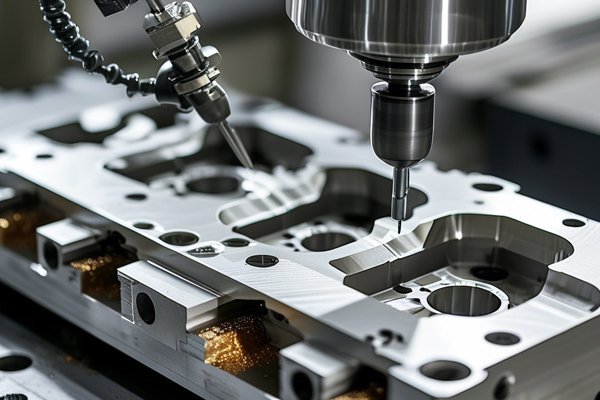

Before delving into optimization strategies, it’s vital to grasp the fundamentals of CNC machining. It involves the automated control of machine tools through computer programming, enabling high precision in cutting, milling, and drilling processes. The CNC machines read CAD (Computer-Aided Design) files, translating digital designs into physical entities with incredible accuracy.

Key Benefits of CNC Machining in Electronic Cigarettes

Identifying Key Areas for Optimization

In the quest for efficiency, it’s essential to scrutinize the entire production process. Here we identify pivotal areas where optimization can be undertaken.

Choosing the right materials for electronic cigarette shells is paramount. Factors such as weight, strength, and manufacturing cost must be balanced. The following considerations can guide your material selection:

The design phase is where many efficiencies can be introduced. Engaging in Design for Manufacturability (DFM) practices can minimize production complexity and reduce costs:

A deep dive into the processes involved in CNC machining can unveil myriad opportunities for improvement.

Integrating advanced technologies is increasingly vital. Automation can scale efficiency dramatically and reduce manual labor costs:

Before committing to full-scale production, rapid prototyping can clarify design effectiveness and production techniques:

Cost Control Strategies

With a clear understanding of the journey towards optimized production efficiency, the next step is implementing effective cost control strategies. Here are several insights to consider:

Accurately forecasting material requirements and costs can help adeptly manage budgets. Establish long-term contracts with trusted suppliers to lock in prices and ensure reliability which protects against sudden price shocks.

Applying lean manufacturing principles can help eliminate wasteful practices:

Investing in the continual training of staff ensures that your team remains competent and informed about the latest techniques, tools, and industry standards:

Leveraging analytics not only aids in identifying manufacturing inefficiencies but also allows for proactive decision-making. Employ data analytics tools to capture and analyze production data, thus enhancing decision-making processes based on hard evidence.

Keep track of costs associated with defects, rework, and returns. By continuously monitoring quality, organizations can become more proactive in addressing issues before they result in significant financial loss.

As we witness the technological shifts within the manufacturing domain, optimizing cost control and production efficiency remains a pivotal area of focus for companies like YL Machining. Through diligent material selection, effective design, enhanced processes, and strategic automation, manufacturers can not only thrive in the highly competitive electronic cigarette market but also deliver unparalleled quality and value to their customers.

Investing time and resources into refining these strategies can yield significant long-term benefits while keeping in mind the ever-evolving landscape of consumer demands and regulations. Embrace change, adopt innovative practices, and above all, remain committed to excellence in every product you manufacture. In a world that constantly shifts toward sustainability and efficiency, staying ahead of the curve is not merely a competitive advantage—it’s a necessity.

Through collaboration and keeping communications open with your partners and stakeholders, we can foresee a bright future ahead for CNC machining in the electronic cigarette industry, ultimately driving it toward new heights of success, efficiency, and sustainability.