: Redefining Precision in Modern Manufacturing

In an era where technological advancements are at the forefront of industrial evolution, the manufacturing landscape is transforming faster than we ever imagined. At the heart of this transformation is a remarkable innovation: 6 axis CNC (Computer Numerical Control) machining. This sophisticated technology not only enhances precision but also drastically improves efficiency in various manufacturing processes. Here at YL Machining, we pride ourselves on leading the charge in integrating such cutting-edge technology into our operations to deliver unparalleled quality to our clients.

As we embark on this exploration of 6 axis CNC machining, you’ll discover insights that transcend mere technical specifications. This article will delve into its transformative potential, how it compares to earlier machining methods, and why it is a game changer for prototyping and production alike. Prepare for an expedition through the intricate world of CNC machining—a journey filled not only with knowledge but with inspiration.

The Foundations of CNC Machining

Before we dive deeper into the specifics of 6 axis CNC machining, it’s essential to understand what CNC machining is at its core.

What is CNC Machining?

CNC machining is a subtractive manufacturing process that relies on programmed computer software to control the movement of machinery and tools. Unlike traditional manual machining, which requires operators to manually guide tools, CNC machining automates the entire operation. This leads to higher accuracy, the ability to repeat exact processes, and reduced human error.

The Pragmatic Evolution: From 3 Axis to 6 Axis CNC

While CNC Machining revolutionized manufacturing in general, the advent of multi-axis machining took this innovation to new heights. Initially, CNC machines were limited to 3 axes: X, Y, and Z. Here’s a brief overview of the evolution:

With the dawn of 6 Axis CNC machining, we’ve reached the pinnacle of precision and versatility.

The Advantages of 6 Axis CNC Machining

The capabilities of 6 axis CNC machining significantly enhance production processes. Below are the foremost advantages that define this advanced technology:

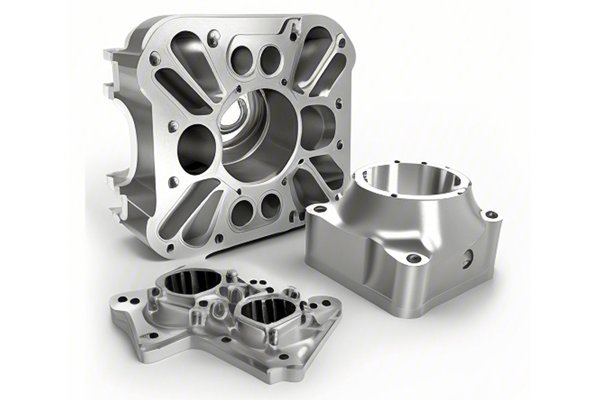

The ability to handle complex geometries is one of the most significant advantages of 6 axis machining. By enabling tool access from various orientations, it can produce intricate shapes that would be impossible with fewer axes. This versatility is especially valuable in industries such as aerospace, automotive, and medical devices, where precision is paramount.

One of the most salient features of 6 axis CNC machining is its efficiency. By eliminating the need to manually reposition parts, production timelines are significantly shortened. This increase in workflow not only maximizes productivity but also reduces labor costs.

With increased control over tool paths and angles, 6 axis machines produce superior surface finishes. This is critical in industries where aesthetics and functionality are linked, such as automotive and consumer electronics.

YL Machining’s 6 axis CNC technology is engineered to work across a broad range of materials, from metals like aluminum and titanium to plastics and composites. This adaptability makes it a favorable choice for a wide variety of manufacturing applications.

While the initial investment for 6 axis CNC machines may be substantial, the long-term savings gained from reduced waste, increased precision, and faster turnaround times make it a cost-effective solution.

Applications of 6 Axis CNC Machining

The versatility of 6 axis CNC machining has facilitated its adoption across diverse industries. Here are some prominent applications:

In the aerospace sector, components must meet exacting specifications for safety and performance. 6 axis CNC machining can produce lightweight, complex geometries that translate into optimal performance while minimizing weight.

From prototyping to mass production, the automotive industry benefits tremendously from 6 axis machining. Whether it’s creating intricate engine components or aesthetic fixtures, this technology streamlines various processes.

Medical implants and devices require a level of precision that 4 axis machines cannot provide. 6 axis CNC machining enables the fabrication of complex shapes suited for implants, ensuring compatibility with human anatomy.

The demand for aesthetically pleasing and functional designs in consumer electronics drives the need for advanced machining capabilities. 6 axis CNC machines allow manufacturers to create precise components that integrate seamlessly into modern devices.

YL Machining’s Approach to 6 Axis CNC Machining

At YL Machining, we are dedicated to staying at the forefront of this technological advancement. Our 6 axis CNC machines are state-of-the-art, equipped with advanced software that allows for complex geometry programming and real-time adjustments. Here’s how we ensure excellence:

We understand that building the prototype is a crucial step in the manufacturing process. Our 6 axis CNC machining allows us to bring concepts to life with accuracy and expediency, minimizing the time from idea to market.

Our team of experienced machinists undergoes constant training to remain adept with the latest technologies. This combination of an intuitive understanding of the machines and the intricacies of design leads to flawless execution.

Quality assurance is paramount at YL Machining. Our meticulous inspection protocols guarantee that every component manufactured adheres to the highest quality standards, minimizing the risk of defects.

We believe in collaboration. By engaging with our clients throughout the process, we ensure that their needs and specifications are met. Our agile approach allows us to make real-time modifications based on feedback, promoting a seamless workflow.

Continuous investment in advanced machinery and software is a hallmark of YL Machining. This includes regular upgrades to our 6 axis CNC systems to keep pace with evolving technological standards.

Overcoming Challenges in 6 Axis CNC Machining

Despite its numerous benefits, 6 axis CNC machining also presents challenges. Here are some common issues and how YL Machining effectively addresses them:

The operational intricacies of 6 axis systems require skilled personnel. At YL Machining, we invest in ongoing training for our staff, ensuring they are well-equipped to handle the complex programming and maintenance that 6 axis machining necessitates.

Creating programs for 6 axis machines can be daunting, given the complexity of movements. Our designers utilize advanced CAD/CAM software to produce precise tool paths, streamlining the programming process.

Maintaining CNC machines can result in significant costs. We practice diligent maintenance schedules and use predictive maintenance technologies to identify potential issues before they escalate, thus optimizing operational costs.

Future Trends in 6 Axis CNC Machining

As technology continues to evolve, so too does the landscape of 6 axis CNC machining. Here are some anticipated trends that promise to further enhance this remarkable manufacturing process:

Artificial Intelligence (AI) is gradually being integrated into manufacturing processes. This will lead to more adaptive machining systems capable of optimizing their operations, minimizing waste, and increasing precision even further.

The Internet of Things (IoT) is transforming manufacturing operations into interconnected systems. This will enable real-time monitoring of machines, enhancing efficiency and reducing downtime through predictive analytics.

As sustainability becomes a paramount concern across industries, advancements in CNC machining will increasingly focus on reducing waste and energy consumption. This includes innovations in tooling and machine usage that promote greener practices.

Personalization will become a defining factor in the upcoming era of manufacturing. The precision of 6 axis CNC machining allows for customization on a scale previously thought impossible, paving the way for consumer-tailored products.

: Embrace the Future with YL Machining

As we explore the future of manufacturing, the relevance of advanced machining technologies—like 6 axis CNC machining—cannot be overstated. At YL Machining, we are not just purveyors of precision; we are innovators at the cusp of a manufacturing revolution. We invite you to collaborate with us to harness the power of 6 axis machining for your next project and experience firsthand how this technology can elevate your products and business.

This journey into the world of CNC machining is just the beginning. As we continue to embrace new technologies and push the boundaries of what’s possible, we stand ready to be your trusted partners in navigating the manufacturing landscape of tomorrow.

—

This article is just a preliminary exploration of a vast and intricate landscape. If you have specific aspects or insights you’d like to explore further within the realm of CNC machining, feel free to let me know!