: The Art of Precision in Modern Manufacturing

In a world where every second counts and every detail matters, the realm of manufacturing has evolved into a landscape of intricate designs, complex specifications, and relentless pursuit of perfection. At the cutting edge of this evolution lies 4 Axis CNC machining— a technology that has not only revolutionized the production process, but has also become a staple in industries ranging from aerospace to automotive, and beyond. In this comprehensive guide, we at YL Machining aim to unravel the intricacies of 4 Axis CNC machining, highlighting its advantages, applications, and its transformative role in the manufacturing landscape.

As we dive deeper into the realm of this innovative technology, we encourage you to explore the depth of precision and creativity it offers, and understand why investing in 4 Axis CNC machining is a strategic decision for forward-thinking businesses.

—

What is 4 Axis CNC Machining?

CNC, or Computer Numerical Control, refers to the automated control of machining tools—like drills, mills, lathes, and 3D printers—via a computer. The addition of an extra axis gives 4 Axis CNC machining a distinct advantage over traditional 3 Axis machining.

Understanding the Axes:

Advantages of 4 Axis CNC Machining

As industries grow more competitive, the demand for precision, speed, and efficiency becomes paramount. Here are several compelling advantages of 4 Axis CNC machining that make it a go-to option for manufacturers.

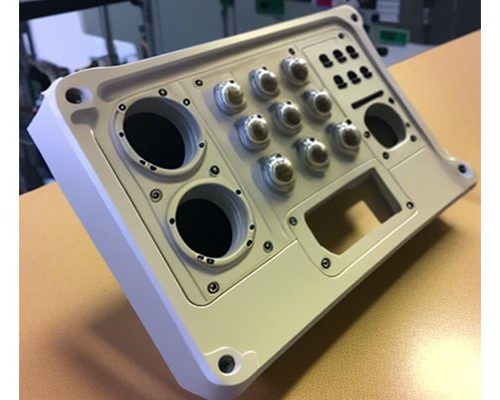

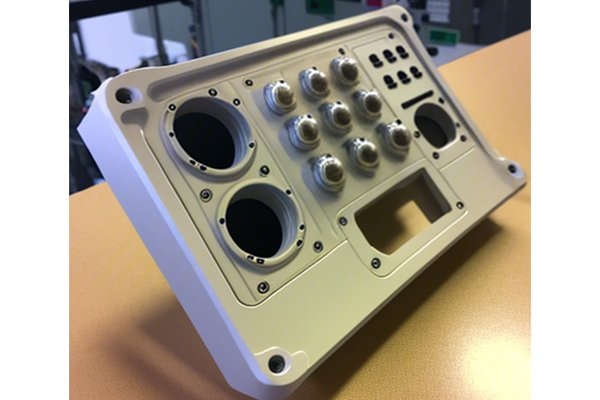

With the ability to rotate the material, 4 Axis CNC machining allows for intricate and detailed designs that would be impossible with just 3 Axis. This capability enables the production of components like complex aerospace parts or intricate medical devices, where precision is non-negotiable.

Transitioning from 3 Axis to 4 Axis means fewer setups and manual adjustments. By allowing the cutting tool to operate on multiple faces without needing to reposition the workpiece, the production timeline is significantly reduced, which translates to lower costs and quicker turnaround times.

The versatility of 4 Axis CNC machining makes it ideal for various industries. Whether it’s creating molds, prototypes, or intricate designs, the 4 Axis approach provides manufacturers with the flexibility to fit their production needs.

The precision that comes with advanced CNC technology means that materials are used more efficiently, minimizing waste. This is not only cost-effective but is also a significant step towards more sustainable manufacturing practices.

Once programmed, a CNC machine can produce parts that are nearly identical to one another, anything from a small batch to mass production runs. The repeatability factor is critical in industries where consistency is key.

Applications of 4 Axis CNC Machining

4 Axis CNC machining has found its footing in numerous sectors. Let’s dive into a few booming applications that highlight the machine’s capabilities.

Aerospace components often have intricate, lightweight designs that must meet strict safety standards. 4 Axis CNC machines can craft complex geometries like turbine blades or housing units that are both precise and lightweight.

From engine parts to custom fittings, the automotive sector utilizes 4 Axis machining for precision-engineered components. Machining efficiencies lead to faster assembly times and improved vehicle performance.

4 Axis CNC machining is leading the charge in producing highly complex medical instruments and devices, allowing for tailor-made solutions that can be produced in less time than traditional methods.

Reducing lead times is vital in the die and mold industry. With its capacity for intricate designs and repeatability, 4 Axis CNC machining excels at creating molds that require high precision and complexity.

When it comes to taking products from concept to market, rapid prototyping is essential. 4 Axis CNC machining enables quick turnarounds on prototypes, allowing businesses to test before committing to mass production.

Choosing the Right CNC Machining Service

As you explore the potential benefits of 4 Axis CNC machining for your business, it’s essential to consider several factors in selecting a machining service provider.

Look for a company, like YL Machining, that specializes in CNC machining with a proven track record in your industry. A provider with experience can offer insights into best practices and ensure your requirements are met.

Ensure the machining service is equipped with the latest technology. Advanced software and hardware are critical for achieving the precision and efficiency promised by 4 Axis CNC machining.

Every project has unique requirements. A machining partner should offer tailored solutions to meet your specific needs, ensuring the final product resonates with your vision.

Quality control is paramount in manufacturing. Your partner should have stringent testing and quality assurance processes in place to guarantee the precision and durability of the final products.

The Future of 4 Axis CNC Machining

As technology continues to evolve, so too will the landscape of CNC machining. Advancements such as AI-integrated machines, better materials, and more intuitive software will drive efficiency and open doors for even more complex designs.

In addition, the rise of Industry 4.0—characterized by automation, data exchange, and IoT—will further enhance the capabilities of CNC machining, paving the way for smarter manufacturing processes that will yield unprecedented levels of precision and productivity.

: Why 4 Axis CNC Machining is Imperative for Tomorrow’s Manufacturing

The journey towards precision manufacturing interweaves technology and creativity, and at its core lies advanced solutions like 4 Axis CNC machining. As businesses strive for excellence and competitive advantage, adopting innovative technologies becomes crucial to their success.

At YL Machining, we pride ourselves on being at the forefront of this manufacturing revolution, committed to providing our clients with the highest standards of service and quality. By embracing the capabilities of 4 Axis CNC machining, you can unlock the potential of your designs, reduce lead times, and elevate your manufacturing processes to unprecedented heights.

In the pursuit of quality and efficiency, let us guide you on this transformative journey. The future of manufacturing is here, and it’s time to embrace it.

—

This article serves as an overview of the myriad advantages, applications, and anticipated trends regarding 4 Axis CNC machining, emphasizing the transformative power that modern machining technologies hold for innovative manufacturers like yourself.