When you think about the machinery that powers modern manufacturing, what comes to mind? For many, it might be the whirring sounds of mechanical tools or the precise movements of robotic arms on an assembly line. But there’s something more nuanced beneath this surface—a magical process happening in workshops and factories that can create intricate parts with incredible precision: CNC parts machining. If you have ever wondered how your favorite gadgets, automotive parts, or even aerospace components are crafted, you’re in for a treat.

In this article, we’ll unravel the complex world of CNC (Computer Numerical Control) parts machining. We’ll explore its principles, advantages, and applications, while also touching upon why this technology has become a game-changer for industries worldwide. Ready to delve deeper? Let’s go!

What Is CNC Parts Machining?

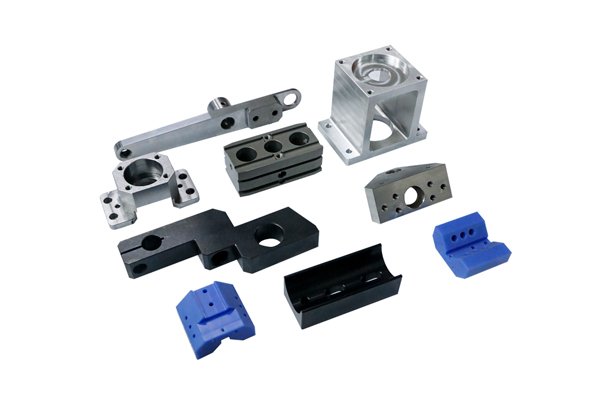

At its core, CNC parts machining is a manufacturing process controlled by computer programming. Picture this: instead of a craftsman painstakingly cutting, drilling, and shaping a raw material—be it metal, plastic, or wood—the CNC machine faithfully executes a digital blueprint to transform that material into a finely tuned component.

Using tools like lathes, mills, and routers, CNC machining takes your digital design and turns it into reality with remarkable accuracy. The result? Parts are produced that are nearly identical every time, with minimal human error.

How Does CNC Machining Work?

So, how does this mysterious process actually unfold? Let’s break it down into digestible parts:

CAD Design: The Blueprint

It all starts with Computer-Aided Design (CAD). Think of it as the architect’s blueprint for a building. This software enables designers to create precise 2D or 3D models of the parts they wish to manufacture. The detail in these designs is pivotal, as even a minor miscalculation can lead to significant consequences during production.

CAM Programming: Translating the Blueprint

Once the CAD design is ready, it’s time for Computer-Aided Manufacturing (CAM) to step in. The CAM software converts the CAD design into a language that the CNC machine can understand, usually referred to as G-code. This code contains instructions on how to move the tools, at what speed, and in what direction—almost like giving the machine a playlist of dance moves!

Machine Setup: Preparing for Production

Before the show can begin, the CNC machine must be prepared. This involves securing the raw material onto the machine, loading the correct tools, and inputting the G-code. It’s a bit like preparing a stage for a performance: every detail counts.

Machining Process: The Performance

With everything set, the CNC machine takes center stage. Following the G-code, it begins to cut, carve, and shape the material with incredible precision. Whether it’s drilling holes, milling surfaces, or turning parts, the CNC machine operates like a finely-tuned orchestra in perfect harmony.

Quality Control: The Final Bow

After the machining process, the parts enter the quality control phase. This is where each piece is meticulously examined to ensure it meets the required specifications. Think of this step as the encore performance; if the audience isn’t satisfied, the show isn’t over yet.

Why Choose CNC Machining?

If you’re still on the fence about CNC machining, let’s take a closer look at some of the benefits. You might find that it’s not just a trendy buzzword—it’s a revolutionary process!

Precision and Accuracy

In the manufacturing world, precision is crucial. CNC machines are capable of producing parts to tolerances of just a few micrometers! Imagine making a puzzle piece that needs to fit perfectly with others—CNC machining ensures each piece will fit together flawlessly every time.

Reproducibility

Consistency is key. Once a design is established, CNC machining can reproduce that part with the same level of detail and precision repeatedly. If you need 1,000 identical components, it’s no problem for a CNC machine—it will crank them out as easily as flipping a switch.

Reduced Waste

Traditional machining can lead to a lot of wasted material due to human error or inefficient methods. CNC machining minimizes waste, as it optimizes the way material is cut and shaped. Think of it like cooking—it’s like using a precise recipe that prevents you from burning or overcooking your meal!

Flexibility in Design

One of the most fascinating aspects of CNC machining is its versatility. Create complex designs that would be impossible or infeasible to manufacture using traditional methods. Just like a sculptor can morph a block of marble into a lifelike statue, CNC machining opens up a world of creative possibilities.

Increased Safety

With CNC machines performing the dangerous tasks of cutting and shaping, human operators are kept at a safe distance from flying debris and sharp edges. This not only improves safety but also allows operators to focus on overseeing the process instead of manual labor.

Applications of CNC Machining

CNC machining is incredibly diverse, serving various industries and sectors. Let’s take a look at some of the most prominent applications:

Aerospace Industry

In aerospace, tolerance levels are critical. CNC machining is used to manufacture components such as turbine blades and brackets with unparalleled precision, ensuring they can withstand the stress of flight.

Automotive Manufacturing

From engine parts to dashboards, the automotive industry relies heavily on CNC machining for its components. The ability to produce parts that fit perfectly is paramount for vehicle function and safety.

Medical Devices

CNC machining is also widely used in the medical field to produce components that require biocompatibility, such as surgical instruments and implants. Precision here can literally mean the difference between life and death.

Consumer Electronics

Think about your smartphone or laptop—CNC machined parts form the backbone of these devices. With the fast-paced evolution of technology, CNC machining is key to producing small, intricate components efficiently.

Artistic and Creative Industries

Even artists have embraced CNC machining to produce intricate sculptures or art installations. With creativity at the helm, this technology can define aesthetic values as much as functional ones.

Common CNC Machining Processes

As with any craft, there are various techniques and methods within CNC machining. Here’s an overview of some popular processes you might encounter:

CNC Milling

This involves using rotating cutters to remove material from a workpiece. It’s like a chef finely chopping vegetables—precision matters to achieve the perfect size and shape! Milling is commonly used for creating flat surfaces and complex shapes.

CNC Turning

In turning, the workpiece rotates while a stationary cutting tool shapes it. This process is similar to a potter shaping clay on a wheel—one tool in motion creates the desired form. It’s typically used for cylindrical components like shafts or axles.

CNC Drilling

As the name suggests, this process uses rotating bits to create holes in the material. Think of it as a drill team executing a perfect formation. While it may seem simple, precise drilling is vital for further assembly and operation.

CNC Electric Discharge Machining (EDM)

This technique is used to create complex shapes by eroding material using electrical discharges. Imagine sculpting a masterpiece by carefully erasing parts of a block—EDM does just that!

CNC Laser Cutting

Laser cutting employs high-powered lasers to slice through materials. Picture a hot knife gliding through butter—it’s that level of efficiency and precision. This process is popular for cutting intricate designs, especially in thin materials.

Challenges in CNC Parts Machining

Now that we’ve painted an optimistic picture of CNC machining, it’s important to acknowledge some challenges:

High Initial Investment

Investing in CNC machinery and software can be expensive. For small businesses or hobbyists, purchasing and maintaining these machines might feel a bit like buying a sports car—fun but potentially daunting!

Skilled Labor Requirement

While CNC technology reduces the need for manual labor, operating these machines still requires skilled personnel. Think of it as having a powerful tool; without someone who understands how to wield it, you might not achieve the desired results.

Maintenance Costs

Like any piece of machinery, regular maintenance is necessary to keep CNC machines running optimally. This can involve additional costs and downtime, much like a car requiring tune-ups and repairs.

The Future of CNC Parts Machining

As we look to the horizon, the future of CNC machining appears promising. With advancements in technology, we’re likely to see:

Greater Automation

With the rise of smart factories and the Internet of Things (IoT), we can expect greater levels of automation in CNC machining. Machines could become more interconnected, sharing data and increasing efficiency without human input.

Integration of AI and Machine Learning

Artificial Intelligence (AI) and machine learning may revolutionize CNC machining. Imagine a machine that learns from its environment and improves its processes based on that learning—efficiency and precision could soar to new heights.

Sustainable Manufacturing Practices

As industries strive for eco-friendliness, CNC machining will undoubtedly evolve to embrace sustainable practices. This could involve using renewable materials, energy-efficient processes, and reducing waste even further.

Conclusion: Embracing the Future

In conclusion, CNC parts machining is an exquisite blend of art and science, making its mark across various sectors and shapes the products we use daily. From the precise engineering of medical devices to the aesthetic beauty of art sculptures, this technology holds immense potential.

As you venture into the world of CNC machining, whether out of professional interest or personal curiosity, remember the transformative power of this innovative approach. Embrace the future of manufacturing, and who knows—you might just find your ideas taking shape in ways you never thought possible!

So, are you excited to explore more about CNC machining? Perhaps you have questions about getting started or specific applications in mind. Feel free to ask—let’s keep the conversation going and dive further into this fascinating world together!