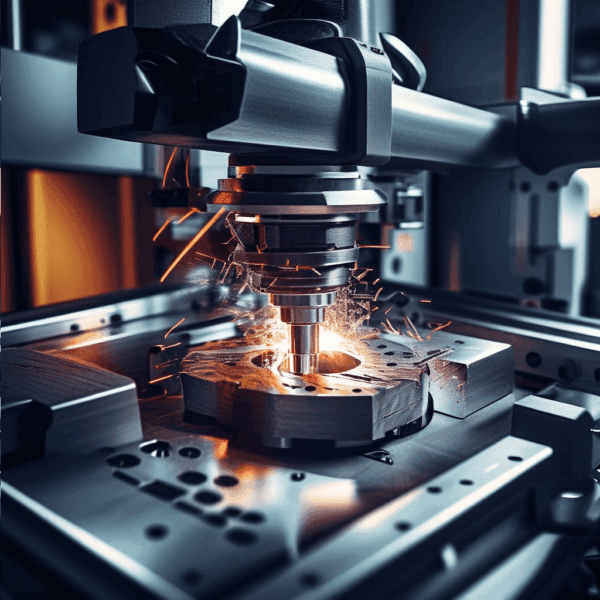

CNC machining of stainless steel parts: advantages and disadvantages of different models

Stainless steel is a corrosion-resistant alloy steel that is widely used in the medical, food processing, aerospace and automotive industries. CNC machining of stainless steel parts can provide high precision and consistency, but different models of stainless steel have different characteristics and challenges when machining. This article will explore the advantages and disadvantages of several […]

CNC machining of stainless steel parts: advantages and disadvantages of different models Read More »

Blog