How Can CNC Milling Enhance the Fitability of Prototype Parts for Improved Performance?

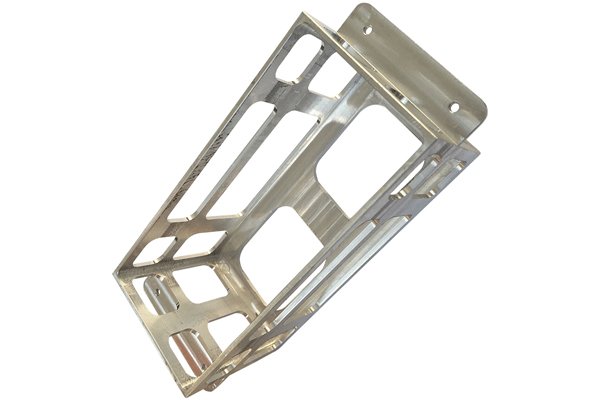

Opening: The Key to Prototype Success Did you know that as much as 60% of project delays in manufacturing can be attributed to the poor fit of prototype parts? In the race for innovation, ensuring that prototype components fit seamlessly can mean the difference between success and failure. This challenge is where CNC (Computer Numerical

How Can CNC Milling Enhance the Fitability of Prototype Parts for Improved Performance? Read More »

Knowledge