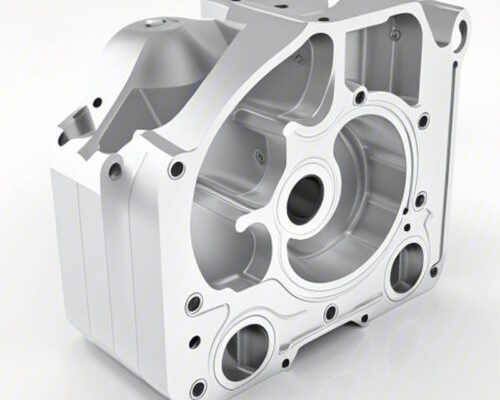

Computer Numerical Control (CNC) machining is a precision manufacturing process that offers high accuracy and repeatability. However, it can also be costly, especially when designing complex parts. To minimize these costs while maintaining quality, consider the following 10 tips:

1. Optimize Part Design for Machinability

Design for Machinability (DFM) principles can significantly reduce CNC machining costs. Streamline part designs to minimize complex features and reduce the number of setups. Avoid sharp internal corners and deep pockets that require special tools or multiple passes .

2. Use Standard Hole Sizes and Thread Lengths

Standard drill sizes and thread lengths can be machined more quickly and accurately. Limit the maximum length of threads to three times the hole diameter to avoid unnecessary costs .

3. Minimize Machine Setups

Design parts that can be machined in as few setups as possible. Multiple setups increase labor and downtime costs. Consider separating parts into multiple geometries that can be assembled later if single-setup manufacturing isn’t feasible .

4. Avoid Small Features with High Aspect Ratios

Features with a high width-to-height ratio are prone to vibrations and difficult to machine accurately. Design features with a width-to-height ratio of less than four and add bracing support if necessary .

5. Remove Unnecessary Text and Lettering

Adding text to CNC parts increases machining time and costs. Use surface finishing methods like silk screening or painting for text instead of engraving or embossing .

6. Choose Materials with Good Machinability

Select materials that are easy to machine. C360 brass and aluminum alloys like 6061 and 7075 have high machinability, reducing machining time and costs. Avoid materials like PEEK and nylon 6 that are more difficult to machine .

7. Consider Material Cost

The price of bulk material affects the overall cost. Aluminum 6061 is cost-effective for prototypes due to its low cost and good machinability. For larger productions, consider materials with higher machinability despite their higher cost, as the reduced machining time can offset the material cost .

8. Limit Surface Finishes

Multiple surface finishes add extra steps and costs. Choose the “as machined” finish or request additional finishes only when necessary .

9. Increase Batch Size for Economies of Scale

Ordering in larger quantities spreads fixed costs like setup and tooling across more parts, reducing the cost per unit. Manufacturers often offer discounts for bulk orders .

10. Simplify Tolerances

Define tight tolerances only when necessary. Standard tolerances are sufficient for most non-critical features, reducing the need for additional machining and inspection time .

By implementing these tips, you can significantly reduce the cost of CNC machining while maintaining the quality and functionality of your parts. Remember, the key to cost-effective CNC machining lies in simplifying designs, choosing the right materials, and optimizing the manufacturing process